Daimler Trucks & Buses investing more on battery-powered trucks

World’s biggest truck manufacturer teams up with China’s CATL to develop battery systems and battery pack assembly as Daimler AG partners with Beijing Electric Vehicle Co., Ltd. to establish 2nd life energy storage systems in China in the future.

Daimler Trucks & Buses is gearing up to power up with lithium-ion battery its global electric trucks set for series

production from 2021 onwards. Last September, Daimler Trucks & Buses signed up an agreement with Contemporary Amperex Technology Co. Limited (CATL) to produce and supply battery cell modules for its global electric truck portfolio that will be introduced in the markets from 2021 onwards, including that of Mercedes-Benz eActros, Freightliner eCascadia and Freightliner eM2.

The heavy-duty Mercedes-Benz eActros with a range of around 200 km is in intensive customer trials as part of an “eActros innovation fleet” in Germany and Switzerland with the first customer hand over in 2018.

The heavy-duty Mercedes-Benz eActros with a range of around 200 km is in intensive customer trials as part of an “eActros innovation fleet” in Germany and Switzerland with the first customer hand over in 2018.

In the United States, the all-electric medium Freightliner eM2 and the heavy-duty Freightliner eCascadia trucks are also in practical customer testing. Around 150 vehicles of the light-duty FUSO eCanter are already in customer operation in cities around the globe such as New York City, Tokyo, Berlin, London, Amsterdam, Paris and Lisbon.

Power-pack partnership

The development of the battery systems lies with Daimler Trucks & Buses. Battery pack assembly will be carried out by Daimler Trucks & Buses as well—at its Mercedes-Benz Mannheim plant in Germany and its Detroit (Michigan) plant in the US, it was disclosed.

“At Daimler Trucks & Buses, we are constantly leveraging our strong technological position and global presence through in telligent platforms and shared modules. We are extending this formula of success to our electric trucks as well, fulfilling our customers’ needs with speed to market and best-available technology. Our E-Mobility Group and the new partnership with CATL are key elements of this approach,” said Dr. Frank Reintjes, Head of Global Powertrain, E-Mobility and Manufacturing Engineering Daimler Trucks.

Gesa Reimelt, Head of E-Mobility Group Daimler Trucks & Buses, noted: “As the world’s leading truck manufacturer, we strive to be first to market with series production zero- emission transportation solutions on a global scale. Already today, we have battery-electric trucks in customer operation around the world. Working with CATL as a strong global partner will go a long way in providing a wide range of electric trucks for series production from 2021 onwards.”

Jia Zhou, President of CATL, said “CATL is committed to drive new energy innovations throughout the world” adding that providing highly efficient electric vehicles is vital to the overall development of the e-mobility market. “Our global partnership with Daimler Trucks & Buses is an important step forward to realize our shared vision of a more sustainable society in the near future.”

Headquartered in Ningde, China, CATL has produced 21.31 GWh worldwide. It has more than 24,000 employees around the world and subsidiaries in Beijing, Liyang(JiangsuProvince), Shanghai and Xining (Qinghai Province), as well as in Munich (Germany), Paris (France), Yokohama (Japan), Detroit (USA) and Vancouver (Canada).

Headquartered in Ningde, China, CATL has produced 21.31 GWh worldwide. It has more than 24,000 employees around the world and subsidiaries in Beijing, Liyang(JiangsuProvince), Shanghai and Xining (Qinghai Province), as well as in Munich (Germany), Paris (France), Yokohama (Japan), Detroit (USA) and Vancouver (Canada).

In addition, the company owns and operates battery manufacturing facilities in Fujian, Jiangsu and Qinghai provinces, and the Europe plant located in Erfurt, Germany, as well as the first overseas plant is under construction. In June 2018, the company went public on the Shenzhen Stock Exchange with stock code 300750.

e-Mobility redefines the future

Since 2018, the E-Mobility Group bundles Daimler Trucks & Buses’ global know-how in the field of e- mobility and defines the strategy for electric components and products across brands and segments.

As is the case with the global platform strategy for conventional vehicles, the E-Mobility Group develops an integrated electric architecture, maximizing the use of synergies and optimizing the application of investments.

At the same time, the E-Mobility Group offers comprehensive consulting for customers and focuses onthe entire ecosystem with the goal to make e-mobility economically feasible also in terms of TCO (Total Cost of Ownership).

The E-Mobility Group is set up globally with employees working in various locations throughout the company’s worldwide development network, i.e. in Portland (U.S.), Stuttgart (Germany) and Kawasaki (Japan).

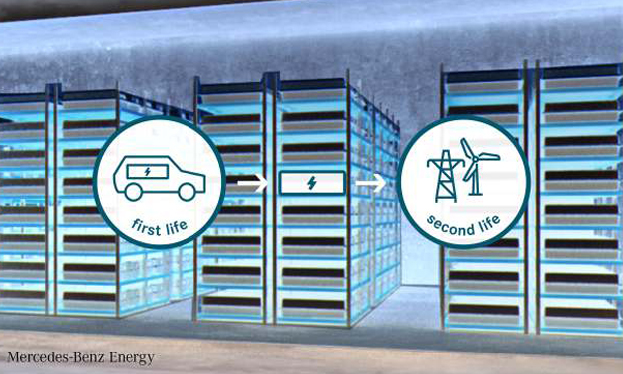

2nd-life energy storage systems

In July, Daimler AG with its wholly owned subsidiary Mercedes-Benz Energy GmbH and Beijing Electric Vehicle Co., Ltd. (BJEV), a subsidiary of the BAIC Group, entered into a development partnership, intending to establish 2nd-life energy storage systems in China in the future.

The companies said the partnership will see a consolidation of expertise and resources regarding the value-chain of automotive battery systems, while laying the ground work for a sustainable renewable energy development.

Together, Mercedes-Benz Energy and Beijing Electric Vehicle plan to set up the first 2nd-life energy storage unit in Beijing, making use of retired BJEV electric car batteries. This project will serve as the basis for other types of cooperation in the future.

Gordon Gassmann, CEO of Mercedes-Benz Energy, creating a sustainable future through responsible use of resources is of paramount concern to the company.

“The extension of regenerative and thus high-fluctuation energy production is rapidly increasing worldwide. The tendency towards increasing distances between the site of energy production and the site of energy consumption also means huge challenges for today’s energy grids.

“This is creating wide-ranging opportunities for stationary energy storage systems worldwide. 2nd-life battery storage units are a very sensible supplement, as with the further utilisation of disused car batteries we are also making sustainable use of valuable raw materials,” said Gassman.

Ye Xiaohua, Deputy General Manager of BJEV, emphasized: “The rapid electrification of vehicles hastransformed vehicles from a traditional means of transport, to a new tool of energy management. BJEV is an expert in areas such as charging and battery swap infrastructure and battery 2nd-life usage. I believe our cooperation in energy management will bring long- term and stable benefits.”

As a subsidiary of Daimler AG, Mercedes-Benz Energy, which is based in Kamenz has been responsible for developing innovative energy storage solutions since 2016. These are based on the automotive battery technology, which is used in electric and hybrid vehicles from Mercedes-Benz and smart.

As a subsidiary of Daimler AG, Mercedes-Benz Energy, which is based in Kamenz has been responsible for developing innovative energy storage solutions since 2016. These are based on the automotive battery technology, which is used in electric and hybrid vehicles from Mercedes-Benz and smart.

The spectrum of large-scale storage applications by Mercedes- Benz Energy ranges from load peak compensation through black start (power system independent start up of the power plant) to uninterrupted power supply (USV).

The company’s focusis in particular on applications from the 2nd-life and replacement parts storage unit sector. Together with its partners, Daimler has already put three mass storage devices with a total energy of 40 MWh from car battery systems into the German grid.

Mercedes Benz Energy also furnished proof together with the transmission system operat or TenneT: automotive battery storage systems can take over tasks from large power stations and make a fundamental contribution towards grid stabilisation and system reconstruction following a power station outage.

The cooperation with the Chinese partner BJEV is now paving the way for the Daimler subsidiary to go abroad. With extensive tests and simulations, the Mercedes-Benz

Energy engineers will demonstrate in the coming months how electric automotive storage units will in future also be able to support the Chinese power grid efficiently and sustainably with regard to fluctuation and power outage management.

Beijing Electric Vehicle Co., Ltd. was established in 2009 by the BAIC Group as a development platform for New Energy Vehicles. With more than 420,000 battery electric vehicles on the market so far, BJEV is one of the leading manufacturers of all-electric vehicles in China.

Accordingly, their batteries form one of the largest pools worldwide and offer wide-ranging potential for 2nd-life applications in the area of stationary use.

In 2016, BAIC established Beijing Articore Battery to perform research into the utilization of 2nd-life batteries. Beijing Articore Battery is currently involved in the research of telecommunications base stations, highway renewable energy stations and mobile energy storage units. Research into micro-grid energy storage is also planned.