DUBAI: The largest mushroom farm in the UAE which produces about nearly 6 tons of mushrooms daily for local consumption and export relies on solar energy and technology to thrive in the region’s harsh weather condition.

Dr. Abdullah Belhaif Al Nuaimi, Minister of Climate Change and Environment, recently met with several local farm owners and discussed ways to enhance and support the emerging agri-tech ecosystem in the UAE, the Emirates news agency WAM reported.

The minister met farm owners, Dr. Ghanem Al Hajri and Ali Bujasim during a tour of the Themar Al Emarat hydroponic farm and the Alayas Farm, respectively.

Located in Sharjah, the 190,000 sqm Themar Al Emarat farm relies on solar energy for 50 percent of its power requirements— power for cooling equipment, water chilling, mushroom cultivation and other greenhouse processes.

It recycles 100 percent of its irrigation water. It also reuses the soil in its hydroponic system as an agricultural conditioner in traditional cultivation. The farm produces mushrooms, lettuce, and other crops used & consumed locally.

Meanwhile, Alayas Farm produces two tons of green fodder that are used as feed for its goats and poultry livestock. It also leverages hydroponics in cultivating vegetables.

The minister stressed that the UAE prioritises the use of agricultural technologies that increase crop production and quality and reduce the environmental footprint of farms across the country. He pointed out that MoCCAE endeavours to strengthen its partnership with major modern farms in the UAE to develop the sector and highlight these farms as successful examples of agri-tech at work.

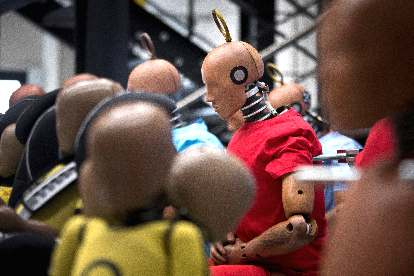

Real accidents planned to be recons-tructed on the computer as a complement to the crash test. Focus was also expanded in line with technological developments in the vehicles – to include systems for active and integral safety.

Colliding with a truck can quickly end up with serious or even fatal injuries whether the collision involves a pedestrian walking on foot, someone inside a car or a bike, because of the huge difference in mass. A collision between two trucks can also result in grave consequences for those involved.

That is why for Mercedes-Benz Trucks safety has always been a priority since 1972 when it established its commercial vehicle accident research center in Germany.

Its top priority has always been to ideally completely avoid this type of scenario or at the very least mitigate the consequences of accidents. Its safety and assistance systems are continually being developed and existing systems optimized specifically for the trucks.

The Group’s Commercial Vehicle Accident Research plays a central role in these efforts. With its accident analyses, it prepares the foundations for continually introducing further improvements to the vehicles.

“We consider our studies to be indispensable for assessing the behavior of a truck in actual accidents,” Kay Morschheuser, Head of Commercial Vehicle Accident Analyses at Mercedes-Benz Trucks, emphasized.

Continuous development process

Continuous development process

This procedure has a tradition: since 1972, the commercial vehicle accident researchers at Mercedes-Benz Trucks have been examining selected accidents with Mercedes-Benz trucks throughout Germany using all the existing and ascertainable information, and documenting data on the course of those accidents, the vehicles involved and the damage – complemented by relevant research by the police rescue teams and experts.

“We also look for conspicuous aspects pertaining to, for example, the frequency of types of accidents, the discernibility of certain patterns of events or to injuries to persons involved in accidents,” Morschheuser explains.

Whereas initially the focus was only on passive safety systems such as the cab structure, restraint systems, front and rear underride guards as well as side protection, that focus was expanded with time – in line with technological developments in the vehicles – to include systems for active and integral safety.

These include systems such as ABS – the Anti-lock Brake System, EBS – the Electronic Brake System and ESP – the Electronic Stability Program or Proximity Control Assist and Lane Keeping Assist as well as Active Brake Assist (ABA), Sideguard Assist or Active Drive Assist.

These include systems such as ABS – the Anti-lock Brake System, EBS – the Electronic Brake System and ESP – the Electronic Stability Program or Proximity Control Assist and Lane Keeping Assist as well as Active Brake Assist (ABA), Sideguard Assist or Active Drive Assist.

Based on their analyses, the accident researchers derive modification measures in close co-operation with the Development department which then often end in future Mercedes-Benz requirements. That is how, several years ago, the idea for Sideguard Assist was developed; since 2016 it has been available for many truck models ex works at Mercedes-Benz Trucks and within its system limits can contribute towards avoiding accidents with pedestrians and cyclists.

Active Drive Assist which allows partially automated driving (level 2) in a truck for the first time ever as well as the MirrorCam instead of the common main and wide-angle mirrors are further more recent examples of the interplay between Accident Research and Development at Mercedes-Benz Trucks.

Crash tests also provide valuable information for safety-oriented development of vehicles

The analyses of Accident Research also go hand-in-hand with the crash tests that have been systematically carried out for years. In this regard the developers and safety experts at Daimler Truck AG have regularly developed their own standards and trials always oriented towards actual accidents in addition to the tests for cab rigidity in line with the EU standard ECE R 29.

One of the most important crash tests is, for example, the impact with a platform vehicle mock-up which reproduces the typical rear-end collision between a truck and a truck driving ahead of it on the motorway.

“In future we will reconstruct real accidents on the computer as a complement to the crash test,” said Morschheuser with a look to the future. The combination of crash simulation and accident reconstruction offers an opportunity to examine accidents more specifically and in more detail with freely selected parameters and thus to better understand the mechanisms in an actual accident.

“Above all it is the circumstances which lead to an accident that are of particular interest to us,” added Morschheuser. In view of the future increase in automated driving and, consequently, the need to have the corresponding systems able to reliably handle the numerous traffic situations, this is a decisive additional benefit.

As the “icing on the cake” of a solid vehicle safety development strategy, the crash tests form a sustainable unit with accident research. This approach also follows the holistic concept of “integral safety” which Mercedes-Benz is now pursuing more than ever, whereby the passive and active systems installed in the vehicle can provide support in four phases: first during driving, second in the event of danger, third in an accident and fourth after a collision.

As the “icing on the cake” of a solid vehicle safety development strategy, the crash tests form a sustainable unit with accident research. This approach also follows the holistic concept of “integral safety” which Mercedes-Benz is now pursuing more than ever, whereby the passive and active systems installed in the vehicle can provide support in four phases: first during driving, second in the event of danger, third in an accident and fourth after a collision.

A glance at general accident statistics reveals just how efficiently this concept, in particular, contributes to traffic safety along with many other measures. According to the German Federal Statistical Office, the number of fatalities in accidents involving trucks in Germany dropped by around 60 percent between 1992 and 2018.

The number of those seriously injured was reduced by about 45 percent during that time. And that despite an increase in transportation of around 80 percent. Accidents with serious consequences are much rarer, although their distribution by type of accident has remained almost unchanged. Rear-end collisions, accidents at junctions and accidents caused by the vehicle leaving its lane remain focal points.

As far as the fundamental development of safety and driver assistance systems is concerned, Mercedes-Benz Trucks has been playing a pioneering role for some time. Photos & Text sourced from: www.media.daimler.com

Its new five-floor regional high-speed logistics hub in Singapore costs EUR101 million, the largest investment in Schenker’s history. It’s fully equipped with the latest automation technology and provides first-class logistics services, including 3D robotic labeling system in multiple languages

B Schenker, the world’s largest logistics provider, marked another milestone in the global transport industry when it unveiled last month its new five-story regional high-speed logistics hub in Singapore known as the “Red Lion.”

B Schenker, the world’s largest logistics provider, marked another milestone in the global transport industry when it unveiled last month its new five-story regional high-speed logistics hub in Singapore known as the “Red Lion.”

The opening of this facility, one of the few large-scale integrated air freight and contract logistics hubs in the world, coincided with the 50th anniversary of DB Schenker’s operations in the Lion City, which is one of the most important logistics hubs in the Asia-Pacific Region (APAC).

Schenker’s first branch in Singapore was set up in 1970. Since then, the business has seen tremendous growth, with the number of locations in the city state rising to 13, including DB Schenker’s regional head office for APAC.

Huge investment

Worth EUR101 million, the Red Lion warehouse is strategically located in the Airport Logistics Park of Singapore (ALPS) at Changi Airport, the site sets a new standard in combining the world’s most advanced technological developments with the highest levels of sustainable warehouse management for its customers.

“DB Schenker further strengthens its position among the world’s leading logistic service providers for the APAC region. Our new logistics hub makes us even faster and more reliable for our customers. The record investment in Red Lion marks an unparalleled milestone for our corporate history of almost 150 years. We are happy and proud to reinforce our commitment to Singapore as the heart of our logistics operations in Asia,” said Jochen Thewes, DB Schenker’s Chief Executive Officer.

Red Lion solidifies Schenker’s position in Singapore as the largest and most advanced third-party logistics provider in the ALPS.

Combined, the mechanized air freight hub and contract logistics warehouse extend over 51,400 square meters on five floors, equal to the size of seven soccer fields.

Innovative & futuristic

A next generation Warehouse Management System and a synchronized IT platform bridging the various automations enable Red Lion to increase warehouse productivity by up to 100% compared to manual processes, and to reduce lead time for customers by 40% compared to non-integrated facilities.

Incoming freight is processed through a ball deck, which increases speed and eases handling. Pallet lifters then move freight to the automated warehouse with Very Narrow Aisles (VNA) to optimize capacity. The multi-shuttle and carton live storage systems are complemented by Goods-to-Person (GTP) and Pick-To-Light technologies, conveyor systems, and Automated Guided Vehicles (AGVs).

Red Lion is also the first warehouse to offer an in-house designed robotic labeling system, which utilizes 3D-vision technology and three robotic arms to apply labels in multiple languages on products of varying sizes, shapes, and configurations.

Red Lion is also the first warehouse to offer an in-house designed robotic labeling system, which utilizes 3D-vision technology and three robotic arms to apply labels in multiple languages on products of varying sizes, shapes, and configurations.

“Our new warehouse is a record-breaking facility full of technological and digital innovations. It is designed to serve customers with requirements for short lead times and high throughput. Our robotics will revolutionize product labelling. With our automation novelties, we are paving the way for our continuous journey in contract logistics toward a fully digital supply chain,” said David Christmas, APAC Contract Logistics Board Member at DB Schenker.

Moreover, the building recognizes Schenker’s commitment to promote sustainable development and environmental protection. 1,440 photovoltaic solar panels, along with other sustainability features, enable energy savings of 34%. Thus, Red Lion is certified with the Green Mark Platinum label by the Building and Construction Authority (BCA) in Singapore as well as the LEED Gold Standard.

DB Schenker, a division of the German rail operator Deutsche Bahn AG, said Schenker Singapore meets changing customer demands in the evolving logistics landscapes through innovations, consistency in quality, and competences in key sectors such as semiconductor, healthcare, aerospace, high-tech and consumer goods. (Photos & Text Source: www.dbschenker.com)

APAC: Fastest growing region in the world

With 4.5 billion people or more than 60 percent of the world’s population located in Asia-Pacific, many of which home to the emerging middle-class, the region is forecast to post the strongest economic growth in the coming years.Despite the pandemic, the region is showing resiliency and recovery, that could spell more business activities in the future.

Singapore, one of the world’s strongest economies, has long recognized the importance of logistics in facilitating economic growth. Before the pandemic, experts forecast the global logistics market to grow by over 7 percent through 2022, largely driven by the rapid growth in the e-Commerce retail industry.

According to Research and Markets, the global logistics market size is projected to grow from USD 2,734 billion in 2020 to USD 3,215 billion by 2021, at a Y-O-Y of 17.6%, in the post COVID-19 era.

The major drivers of this market are increasing focus on the continued supply of essential commodities, creation of supply chain stabilization task force to fight COVID-19, and growing demand and distribution of personal protective equipment, the research intelligence firm added. Fast-moving consumer goods (FMCG) and healthcare products will dominate the logistics market.

On top of speed and operational excellence, one of the strengths of our industry is our professionalism and the great people who are part of the air cargo family. I am glad this crisis has revealed the air cargo heroes and hope this will not be forgotten.

Q&A with TIACA Chairman Steven Polmans

No one could have predicted that an unknown, invisible virus would shut the world for months, bury people and businesses in debt as well as cripple robust industries and economies in unimaginable proportions.

The Coronavirus pandemic is a tragic part of modern history that will be looked back upon with great sadness. It killed more than 900,000 people and infected nearly 28 million worldwide, thus far; millions have lost their jobs and billions across the planet still live in uncertain times.

The story doesn’t definitely end there. The pandemic remains a threat to all of us and certain industries like air cargo must double its efforts to step up to the plate and keep things going.

Steven Polmans, Chairman of The International Air Cargo Association (TIACA), the only global trade organization for the industry, shares his insights with Air Cargo Update, the industry’s growing importance to sustain lives, businesses and economies during these difficult times.

Steven Polmans, Chairman of The International Air Cargo Association (TIACA), the only global trade organization for the industry, shares his insights with Air Cargo Update, the industry’s growing importance to sustain lives, businesses and economies during these difficult times.

One of the industry’s most crucial missions is to deliver billions of COVID vaccines once it gets the green light for distribution.

Worldwide, at least 578 drugs and vaccines are reportedly in development targeting the virus. 34 of these are now in final clinical evaluation with the global biopharmaceutical industry innovating and fast-tracking everything.

Approximately 12-15 billion doses of the vaccines are needed, but there’s no assurance that much could be produced immediately given the manufacturers’ limited facilities and resources. Some vaccines may require just one dose, others up to three doses, requiring more production and shipments, according to experts.

The air cargo industry, which has shown its agility, flexibility, reliability and innovation during the pandemic, is crucial in hauling the vaccines around the world. Is it ready? The honest answer is not yet but it’s up to the challenge.

Read the rest of our interview with Polmans, who is also the Brussels Airport Director for Cargo & Logistics and Chairman of Air Cargo Belgium.

It’s been widely circulated in the industry that you’ve decided to leave Brussels Airport as Director Cargo and Logistics. What prompted this decision and what’s next for a man of your caliber who is known for growing Brussels’ cargo business and pushing for the industry’s agenda in general.

The past 10 years were remarkable, and with my team, we have been able to really turn the cargo business in Brussels into a success story. Increasing revenue and profitability, complete overhaul of the infrastructure, setting up a cargo community, digitization initiatives to make Brussels the smartest airport. So, I can only say I look back at this period with great pride and positive feelings.

But after 10 years, I also felt I needed something new, something challenging, pushing me a bit out of my comfort zone again. So, we were able to end my contract in good terms and I am really looking forward to what comes next. It is the first time in my life I am not having a job, so it is also new to me. Hopefully, however it will be in this industry as I really like it and I feel there is still so much that can be done and where I believe I could contribute.

You’ve been the Chairman of TIACA very recently but its membership has remarkably grown with strategic alliances with some industry groups. How did you do this? What can you say about this feat?

As the unique not-for-profit industry association representing and uniting the global air cargo community, we believe it is important to ensure our membership is diverse in terms of stakeholder type, company size, geographic location. Since last September, we did several things to increase the membership of TIACA:

We signed a partnership with Neutral Air Partner (NAP), a premier global network of 250 leading air cargo architects and aviation specialists from 150 countries, making all NAP members also TIACA members.

We introduced a separate category for small, medium and start-up companies allowing them to become a full TIACA member at reduced rate, as we believe it is the mission of TIACA to represent and unite the global air cargo industry, regardless of the size of the company and welcoming new entrants.

We launched the Sustainability program last year and project Sunrays this year, as a start to morph TIACA into a content-driven association. This evolution is attractive to companies who want to contribute to such initiatives.

Regrettably, as the industry is suffering and many companies are struggling to survive, we are also losing some members due to the COVID-19 crisis.

The Coronavirus pandemic has exposed vulnerabilities & strengths in certain industries. Please relate those weaknesses and strengths in the air cargo industry.

Weaknesses of our industry were already known: fragmented, complex procedures, slow digitalization, complexity in the certification and use of active monitoring devices, lack of clear visibility of existing capabilities of airfreight players at each location or by trade-lane.

We “discovered” at the start of the crisis our extreme reliance on passenger traffic to provide airfreight capacity. Capacity shortage was not an issue before, except at very peak times linked to Christmas and Single Days, but it is anticipated to be one of the major issues in the next months and years, until belly capacity is back.

We “discovered” at the start of the crisis our extreme reliance on passenger traffic to provide airfreight capacity. Capacity shortage was not an issue before, except at very peak times linked to Christmas and Single Days, but it is anticipated to be one of the major issues in the next months and years, until belly capacity is back.

On top of speed and operational excellence, one of the strengths of our industry is our professionalism and the great people who are part of the air cargo family. I am glad this crisis has revealed the air cargo heroes and hope this will not be forgotten

Another strength, despite opposite perception, is our great innovative mindset: airlines, handlers, airports, civil aviation authorities, manufacturers have all came up with solutions to the problems. The new “preighter” operations, Cargo in the Cabin, new equipment design to support them like Cargo Chute from JBT are prime examples of exceptional reactivity and solution-oriented approach we have in our industry.

What are the greatest challenges impacting the global air cargo industry’s growth and transformation in the digital age?

In the COVID-19 era, this is airfreight capacity, cash shortage and budget cuts affecting investments in infrastructure, both physical and digital. Before COVID-19, it was the slow pace of digital transformation mainly due to mindset and lack of priority given to cargo compared to passenger or to air compared to surface modes of transport.

In the post-COVID-19 era, we are hopeful that the profile of air cargo will be raised and heads of cargo will be invited more and heard better at Board discussions, that talented professionals will be willing to join and stay in this industry and drive its digital and sustainable transformation.

TIACA’s influence in the air transport industry is getting stronger as its responsibilities to safety transport vital goods across the world gets bigger. How is TIACA taking its role in this difficult and challenging times?

While the world is discovering air cargo’s vital role for a sustainable world, it is important for industry associations like TIACA to build on it and make the voice of our industry heard more and better.

TIACA is more relevant than ever in this context and to prepare the “next normal” as we are the only international trade association representing and uniting the global air cargo community.

TIACA’s challenge is to pursue its advocacy mission to defend the interests of our members and the industry, but also to set the vision for the future, building on strong partnerships, and developing products and services our members need now and will need tomorrow. We have to be visionary and pragmatic at the same time: this is our commitment to our members.

How do you help members adopt to the new normal, particularly those with no access to government assistance?

We are not yet in the new normal, times are still very uncertain. For a lot of smaller companies, this is having a bigger impact than for global companies with more support functions. Especially for those companies, joining a bigger alliance or association such as TIACA can help. We do have government contacts and access to other organization.

In recent months, several times, we were able to help individual members struggling to get their issues on the agenda of governments and authorities. When dealing with this crisis, decisions were taken that impacted passenger traffic but indirectly also cargo, often unknown or without realizing the impact. TIACA can help to create awareness and push to have cargo higher on the agenda.

There’s been plenty of talks a COVID vaccine is likely to be distributed for commercial use very soon. How prepared is the air cargo industry in undertaking this great task in your opinion?

The industry is not prepared yet, as we lack critical information of the future vaccines specifications, production locations, volumes, etc. But we are working on that.

Last month, TIACA joined forces with Pharma.Aero to launch project Sunrays. Our objective is to open dialogue with pharmaceutical manufacturers to collect these insights, as well as to gather intelligence on airfreight industry’s overall capabilities, plans and readiness to handle, store, transport and deliver the future vaccines.

What advice would you give air cargo carriers and logistics companies running cold chain facilities to efficiently handle this mission with billions of vaccines out to be distributed globally?

I am sure they are already doing it, but in case they are not, I would recommend they start discussing with their forwarders and pharmaceutical shippers now, do an inventory of their capabilities (in terms of skills/trained personnel; cool chain facilities, ground service equipment, ULDs, tracking devices, etc.), develop dedicated operating procedures to handle, store, transport and deliver the vaccines; set up dedicated teams; define what to do with the other cargo requests and manage customers expectations to avoid frustration, etc.

Air transport in developed nations are reliable but some remote areas as well as those facing civil and political unrest don’t have access to it. Is TIACA considering talks with international bodies to help in this area? Why or why not?

Yes, as much as possible, we would like to cooperate with international organizations like WHO, GAVI or UNICEF and share with them the intelligence we will gather. Our ambition is do ourselves what we are best in, and support others and join forces if it makes sense.

Please share some lessons we all could learn from this pandemic.

Still a bit early, as this pandemic is not over yet. We are not back to the new normal and I am also sure that seen the impact on (passenger) aviation on which we depend a lot, the future will look different.

But looking back, I think we must be very proud as an industry on what we did. We have shown agility, flexibility, determination, action and solution focused thinking. But all the weaknesses of the past are not gone: for me the biggest lesson is that this slow adoption of digitization, the lack of cooperation are things we need to tackle soonest.

Steven Polmans: Man of the Hour

Steven Polmans spent most of his career in the world of aviation and held management positions, both operational and commercial, in the handling industry.

Steven Polmans spent most of his career in the world of aviation and held management positions, both operational and commercial, in the handling industry.

On October 1, 2010, he joined Brussels Airport as Cargo Marketing Manager and on February 1st, 2012, he was appointed Head of Cargo and Logistics, responsible for developing and implementing the overall cargo strategy of the airport.

In 2016, Steven became one of the founding fathers of Air Cargo Belgium and was chosen to become the first chairman of this newly established air cargo organisation at BRUcargo, grouping all stakeholders involved.

In August of the same year, Steven also joined the board of TIACA, The International Air Cargo Association, of which he became Vice Chairman in October 2017. On April 1st, Steven was promoted to Director Cargo & Logistics and amongst his new responsibilities is becoming in-charge of all cargo real estate development and portfolio management.

In July 2019, Steven took over the role of Chairman at TIACA, a position he still holds today.

Time and again, we are shown that a degree doesn’t define a person’s success in life but rather his passion to make a difference in his chosen path.

Bill Gates, the tech billionaire ranked as the world’s wealthiest person before Jeff Bezos of Amazon took over this year with assets of over $105.6 billion, dropped out of college at Harvard while making Microsoft. So, did the late Steve Jobs of Apple. He stopped his university studies and instead went to India to study Buddhism.

In France’s logistics industry, Joël Glusman who never finished college, is a name to be reckoned with.

Glusman, the President & CEO of Crystal Group and TALA, the aerospace logistics alliance in France, who is also a TLF Board Member & Foreign Trade Advisor of France, began his career at age 17 as an airport field messenger at Orly Airport in 1974.

Passionate with what he’s doing with a quest for knowledge, Glusman managed to climb up key positions in the industry, including becoming VP for sales and marketing stationed in New York for a major French international freight forwarder.

Well-versed in English and well liked by his peers, Glusman joined Qualitair and Sea in 1990 after returning to France. By 2007, he led a management buyout and Crystal Group was created and he became the company’s CEO and President.

Combining organic growth with some acquisitions, Crystal Group is today considered one of the largest independent logistics providers in France.

“We started this business in 1986. It’s more than 34 years ago. The challenges were just crazy but we managed to overcame those,” shared Glusman to Air Cargo Update in an interview in Dubai where his firm participated at an MRO event held just before the COVID-19 lockdown in March.

“What we learned is that ethics in doing business is really important. You must also have the passion for your customers and the aerospace industry,” he added noting that his company mainly deals with providing logistics for the aerospace industry.

Today, Crystal Group is one of the most trusted names in the aerospace logistics in France which has also expanded its network to the Middle East, Europe and beyond. Worldwide, Glusman employs about 600 staff.

“I’m driven by passion,” said Glusman who continues to break new opportunities for his company by adopting and blending technology to what they do.

“There will always be giants like UPS, FedEx, DHL and we need those guys. Smaller companies like us provide added value services to them by improving the supply chain,” he added.

A devoted father to his two sons and his wife, his childhood sweetheart, Glusman finds joy splitting time between work and family.

“I like spending time with my family,” said Glusman who is also a grandfather to an adorable girl.

This French entrepreneur says his family’s strong support and undivided commitment to his endeavors enabled him to accomplish many things in life. Priceless.

CHAMP Cargosystems has selected Google Cloud to provide an application programing interface (API) platform and ‘self-service portal’.

The platform, Google Cloud’s Apigee API management portal, allows CHAMP and its customers to quickly connect to a variety of back end systems, including in-house and third-party apps, marketplace portals, and more.

It also allows developers to take advantage of APIs to invent new use cases.

Lee Booth, vice president global products at CHAMP Cargosystems, said, “Our customers want solutions that can quickly scale up with their growth and meet their complex localization needs. By partnering with an industry leader in data and information technologies, we can provide that across the industry.”

FarEye, a logistics SaaS platform for predictive visibility, recently announced that it has raised additional $13 million as an extension to its Series D investment led by The Fundamentum Partnership, the growth-capital fund for mid-stage technology companies in India backed by Nandan Nilekani and Sanjeev Aggarwal and KB Global Platform Fund, one of the leading investment firm of Korea.

The investment will accelerate FarEye’s global expansion to address the steepening digital curve for logistics transformation. The need is being further accelerated by enterprises and end consumers demanding a high level of transparency, faster and more convenient delivery experiences. There is also an increased need for flexible supply chains to meet these demands.

FarEye works with its enterprise customers to provide higher control on their supply chains and offer a superior delivery experience to their end customers. The company’s technology platform digitizes the way enterprises dispatch, execute, track, and optimize the movement of goods, enabling enterprises to lower logistics costs while delighting end consumers.

“The support and trust of our investors, customers, and partners underpin our deep desire to make logistics better for brands, their customers, and the environment. We are seeing a surge in the need for real-time visibility in logistics for businesses to build customer-centric supply chains. With recently raised funds we will continue to invest in the best talent in the Americas, Europe, and APAC to support our hyper-growth in these regions. With a vision to make FarEye one of the most customer-centric organizations globally, we aim to make every delivery delightful for the consumers.” said Kushal Nahata, CEO, FarEye.

Commenting on the investment Sanjeev Aggarwal, co-founder of Fundamentum said, “Investment in the logistics space is essential for the economic growth of any nation. FarEye has captured the pulse of this industry and has all the ingredients to head towards global leadership. I believe in the founders, and the team has the clarity of vision. We are excited to partner with FarEye in its journey to create a global technology leader in the logistics space.”

This is the second time this year that FarEye has been able to raise funds to support its hyper-growth in global markets, making it a total of USD 51 Mn investment so far. In April, FarEye had raised USD 24.5 Million in Series D from M12 (Microsoft’s venture fund) with participation from Eight Roads Ventures, Honeywell Ventures, and existing investor SAIF Partners.

FarEye’s recent success in Europe with marquee customers like the leading postal and logistics service company in Finland and a leading American eCommerce company among others has fueled its focus for rapid expansion in the region. Recently FarEye established its European headquarters in London and continues to invest in building its sales, solutions, services, and customer success teams in the region.

The region’s largest full spectrum factory and warehouse automation solution provider, ACME Intralog, reports increase in demand for their solutions as the ‘new normal’ signifies radical change in the way businesses look at their distribution centers. The disruption in logistics during Covid has made more companies look to established regional players like ACME for warehousing automation as opposed to hiring companies outside the region.

CEVA Logistics, part of the CMA CGM Group, has commenced the rollout of CargoWise, the integrated logistics execution platform. With this strategic investment, CEVA Logistics will simplify and standardize all 4PL operational processes across its global network. CargoWise will be implemented over the course of the next five years, as part of a planned process, replacing multiple legacy systems and delivering greater efficiency within the business.

The switch to CargoWise will enable CEVA Logistics teams around the globe to have real-time visibility of freight forwarding and Customs actions on a single platform. As a purpose-built solution, Cargowise gives employees access to the same information in a single database across all functions, offices, countries and languages, furthering the CEVA Logistics digital transformation.

By the end of 2022, 50% of all CEVA Logistics locations will be fully operational on the CargoWise platform with the whole project completed and deployed by 2025.

The move to CargoWise is a key part of CEVA Logistics’ IMPACT 2020 plan which aims to both grow the business and improve operational efficiency. Other recent investments as part of that plan include the purchase of a majority stake in AMI Manica in Africa and the launch of the MyCEVA platform for customers.

Says CEVA Logistics’ CEO, Mathieu Friedberg: “By implementing CargoWise, CEVA Logistics will further improve productivity and efficiency as we strive to lead the way in multi-modal forwarding and contract logistics operations. Thanks to its experience across the transport and logistics sector, CargoWise is the right choice to provide this new digital platform. CEVA Logistics recently invested to improve the customer journey and this implementation allows us to develop a high-level employee journey as well.”

WiseTech global founder and CEO, Richard White, said: “We are extremely pleased to welcome CEVA Logistics to our global rollout family. This is a fantastic decision for their business and its thousands of logistics specialists.

“The world of logistics has experienced significant upheaval over the past six months with the digitization and automation of processes critical for future success. CargoWise will empower and enable CEVA Logistics to significantly improve efficiencies across its logistics and supply chain operations and continue to build its presence and strength globally.”

Licensed across 160 countries, WiseTech’s flagship logistics platform, CargoWise, enables logistics service providers to execute highly complex transactions in areas such as freight forwarding, customs clearance, warehousing, shipping, tracking, land transport, e-commerce, and cross-border compliance, allowing them to manage their operations on one database across multiple users, functions, countries, languages and currencies.

Global warehouse automation specialist, Swisslog, has announced the successful installation and implementation of a new fully-automated and retrieval solution for Mai Dubai, a leading Dubai-based bottled drinking water company.

The move is part of Mai Dubai’s ongoing expansion initiative and involves the implementation of a fully automated and data driven intralogistics system that is in line with industrial revolution 4.0.

As part of an order valued over Euro 20 million, Swisslog planned and implemented a fully automated system based on intelligent software in the context of big data.

The major expansion project included planning and implementing a six-aisle automated high-bay warehouse for raw material and packaging materials as well as -only a few hundred meters away- a high-bay warehouse with 17,560 pallet locations for finished goods with 10 aisles.

The use of Swisslog’s fully automated storage and retrieval solution will help drive key benefits and advantages for Mai Dubai, including a significant reduction in labor costs, improved production and enhanced storage efficiencies.

The installation proves to be both timely and strategic – expecting to sustain Mai Dubai’s continuing growth since its inception in December 2012. The company, which is already widely recognized for its excellent reputation, is the official bottled water partner of Emirates Airlines and has also become a household brand name in Oman, Bahrain, and 13 other countries across Asia, Europe and Africa.

Alain Kaddoum, General Manager, Swisslog Middle East, commented, “Warehouse and factory managers constantly need to synchronize their material flow between production and warehouse to optimize the inventory level and reduce the operational costs.

“The introduction of new automation deployments driven by strong warehouse management software (WMS) can maximize return on investment and minimize risks to supply chain operations. Combining Swisslog’s SynQ WMS solution, Mai Dubai were able to modernize their warehousing, distribution and fulfilment operations by optimizing the performance of front-line workers, speed up production and maximize the storage capacity.”

The installed Swisslog solutions included the Vectura pallet stacker cranes (ASRS), which are known for its optimized energy-efficient design and delivery of highly efficient storage and retrieval with minimal energy costs; a monorail system complete with 44 trolleys; a ProMove pallet conveyor and lifting systems that ensure the efficient flow of goods and sequencing of pallets in receiving and shipping.

The company also deployed an advanced high-performance information technology (IT) infrastructure and controls systems, the Swisslog Warehouse Management Software (SynQ), which allows for real-time 3D visualization and condition monitoring of the entire operations.

The modular software platform also offers a number of big-data business intelligence tools that can be flexibly added over the time. With its modular architecture and user-friendly design, the WMS software helps Mai Dubai to be prepared for the future.

Alexander van ‘t Riet, CEO of Mai Dubai LLC, said, “We are very excited about the potential benefits to be gained from the installation of this new fully automated storage and transport system from Swisslog. Working closely with Swisslog was part of our expansion strategy. In fact, the implementation of an automated and digitalized logistics solutions is part of and contributes to our customer-focused approach. This initiative has helped us not only to improve our production control but also allowed for greater storage density and increased efficiency.”

The International Air Transport Association (IATA) announced that Muhammad Albakri, IATA’s regional vice president for Africa and the Middle East (AME), will be appointed senior vice president for customer, financial and digital services (CFDS), based in Geneva.

The position will be effective 1 March 2021.

At that time Aleks Popovich, who currently holds the position, will retire.

“Over the past 16 years Aleks has driven some of the most critical elements of IATA’s operations, while leading major transformational projects for the airline industry. This includes IATA’s financial settlement products, which securely processed $457 billion of industry money in 2019, during a time of tremendous innovation in financial technology. And he delivered critical flagship programs that continue to change the industry—introducing cost-effective self-service options under the banner of Simplifying the Business, enabling airline retailing with New Distribution Capability (NDC), and streamlining decades of legacy processes with ONE Order. Aleks leaves behind a great team with a clear focus on customer service that will continue to drive critical changes under the capable leadership of Muhammad,” said Alexandre de Juniac, IATA’s director general and CEO.

Albakri joined IATA in January 2017 after more than a decade in the leadership team of Saudi Arabian Airlines where he successfully fulfilled the roles of Chief Financial Officer, Chief Information Officer and Senior Vice President for Transformation. At IATA, Albakri has been an agent of change, transforming the Africa and Middle East regional team to better serve member needs and pioneering the work of IATA’s Digital Transformation Advisory Council.

“Muhammad is well prepared to guide the development of IATA’s commercial offerings, settlement services and digital leadership. In normal times, these are critical functions—even more so in the middle of an industry crisis,” said de Juniac.