You probably heard about ACL Airshop, the tech- driven leading worldwide provider of ULDs, cargo control and air freight products and services to more than 200 airlines across six continents and at majority of the world’s top 100 air cargo hub airports.

Behind its success is actually its first employee, Jos Jacobsen, now ACL Airshop’s Managing Director Europe for Global Leasing & Technology.

After completing his Business and Accounting with Variant Management and Information Degree, Jos began working for Airshop in 2002. Nearly a decade later and after numerous promotions, he was moved to Hong Kong to set up the firm’s Asian operation.

Steve Townes, the West Point Military Academy graduate, founder, CEO & President of Ranger Aerospace LLC and its affiliates, concurrently the Chairman & CEO of ACL Airshop, is all praises for Jos.

“His 17 years of progressive advancements in the ACL Airshop enterprises have, thus far, culminated in his very senior leadership role as our #1 international executive, CTO, and global leasing “dynamo.” He almost single-handedly set up our burgeoning Asia- Pacific operations some years ago with one outpost in Hong Kong. Now we have 16 support centers over there, plus manufacturing supply chain extensions in China and Taiwan, and in Q1 of next year we intend to commence air cargo logistics support operations in India,” said Steve.

Steve also credited Jos for steering ACL Airshop to the digital age describing him as “the driving force behind our numerous new technology initiatives.”

“Jos has also been the driving force behind our numerous new technology initiatives. Proprietary repair stations software, upgraded ERP systems, robust “Ops Centers” in three major gateway cities, proprietary “ULD Control” logistics management programs, Bluetooth real-time tracking and tracing, and now “FindMyULD” App are, altogether, an incredible body of work,” said Steve noting that in the past four years, ACL had grown its fleet of ULDs to more than 50,000 with leasing support operations at 52 of the world’s top 100 cargo airports.

Jos, now a father of two young boys, who also owns a red cat, says though his job demands a lot of responsibilities and focus, he still finds time to unwind. “My family at home is most important to me and spending time with them is relaxing. And I love to listen to ’80s music,” shared Jos now based in The Netherlands.

He is also into a lot of sports, keeping him fit and healthy. “I am always training for triathlons. Running, cycling and swimming are part of my daily routine. My goal is to keep improving and compete in races.”

And when life turns sour at times, Jos says he keeps his cool playing his favorite songs from the ’80s and reminding himself that life is too short to be wasted.

“Life is too short to worry about stupid things. You only live once, you better enjoy it,” Jos told Air Cargo Update when asked about his favorite inspiring quotes he holds on to when he’s feeling blue or down.

“And listening to some good ’80s songs from Don Henley, Foreigner, or Fleetwood Mac always helps.”

World’s biggest truck manufacturer teams up with China’s CATL to develop battery systems and battery pack assembly as Daimler AG partners with Beijing Electric Vehicle Co., Ltd. to establish 2nd life energy storage systems in China in the future.

Daimler Trucks & Buses is gearing up to power up with lithium-ion battery its global electric trucks set for series

production from 2021 onwards. Last September, Daimler Trucks & Buses signed up an agreement with Contemporary Amperex Technology Co. Limited (CATL) to produce and supply battery cell modules for its global electric truck portfolio that will be introduced in the markets from 2021 onwards, including that of Mercedes-Benz eActros, Freightliner eCascadia and Freightliner eM2.

The heavy-duty Mercedes-Benz eActros with a range of around 200 km is in intensive customer trials as part of an “eActros innovation fleet” in Germany and Switzerland with the first customer hand over in 2018.

The heavy-duty Mercedes-Benz eActros with a range of around 200 km is in intensive customer trials as part of an “eActros innovation fleet” in Germany and Switzerland with the first customer hand over in 2018.

In the United States, the all-electric medium Freightliner eM2 and the heavy-duty Freightliner eCascadia trucks are also in practical customer testing. Around 150 vehicles of the light-duty FUSO eCanter are already in customer operation in cities around the globe such as New York City, Tokyo, Berlin, London, Amsterdam, Paris and Lisbon.

Power-pack partnership

The development of the battery systems lies with Daimler Trucks & Buses. Battery pack assembly will be carried out by Daimler Trucks & Buses as well—at its Mercedes-Benz Mannheim plant in Germany and its Detroit (Michigan) plant in the US, it was disclosed.

“At Daimler Trucks & Buses, we are constantly leveraging our strong technological position and global presence through in telligent platforms and shared modules. We are extending this formula of success to our electric trucks as well, fulfilling our customers’ needs with speed to market and best-available technology. Our E-Mobility Group and the new partnership with CATL are key elements of this approach,” said Dr. Frank Reintjes, Head of Global Powertrain, E-Mobility and Manufacturing Engineering Daimler Trucks.

Gesa Reimelt, Head of E-Mobility Group Daimler Trucks & Buses, noted: “As the world’s leading truck manufacturer, we strive to be first to market with series production zero- emission transportation solutions on a global scale. Already today, we have battery-electric trucks in customer operation around the world. Working with CATL as a strong global partner will go a long way in providing a wide range of electric trucks for series production from 2021 onwards.”

Jia Zhou, President of CATL, said “CATL is committed to drive new energy innovations throughout the world” adding that providing highly efficient electric vehicles is vital to the overall development of the e-mobility market. “Our global partnership with Daimler Trucks & Buses is an important step forward to realize our shared vision of a more sustainable society in the near future.”

Headquartered in Ningde, China, CATL has produced 21.31 GWh worldwide. It has more than 24,000 employees around the world and subsidiaries in Beijing, Liyang(JiangsuProvince), Shanghai and Xining (Qinghai Province), as well as in Munich (Germany), Paris (France), Yokohama (Japan), Detroit (USA) and Vancouver (Canada).

Headquartered in Ningde, China, CATL has produced 21.31 GWh worldwide. It has more than 24,000 employees around the world and subsidiaries in Beijing, Liyang(JiangsuProvince), Shanghai and Xining (Qinghai Province), as well as in Munich (Germany), Paris (France), Yokohama (Japan), Detroit (USA) and Vancouver (Canada).

In addition, the company owns and operates battery manufacturing facilities in Fujian, Jiangsu and Qinghai provinces, and the Europe plant located in Erfurt, Germany, as well as the first overseas plant is under construction. In June 2018, the company went public on the Shenzhen Stock Exchange with stock code 300750.

e-Mobility redefines the future

Since 2018, the E-Mobility Group bundles Daimler Trucks & Buses’ global know-how in the field of e- mobility and defines the strategy for electric components and products across brands and segments.

As is the case with the global platform strategy for conventional vehicles, the E-Mobility Group develops an integrated electric architecture, maximizing the use of synergies and optimizing the application of investments.

At the same time, the E-Mobility Group offers comprehensive consulting for customers and focuses onthe entire ecosystem with the goal to make e-mobility economically feasible also in terms of TCO (Total Cost of Ownership).

The E-Mobility Group is set up globally with employees working in various locations throughout the company’s worldwide development network, i.e. in Portland (U.S.), Stuttgart (Germany) and Kawasaki (Japan).

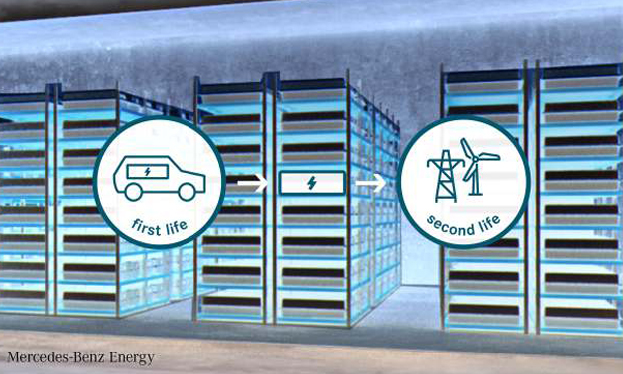

2nd-life energy storage systems

In July, Daimler AG with its wholly owned subsidiary Mercedes-Benz Energy GmbH and Beijing Electric Vehicle Co., Ltd. (BJEV), a subsidiary of the BAIC Group, entered into a development partnership, intending to establish 2nd-life energy storage systems in China in the future.

The companies said the partnership will see a consolidation of expertise and resources regarding the value-chain of automotive battery systems, while laying the ground work for a sustainable renewable energy development.

Together, Mercedes-Benz Energy and Beijing Electric Vehicle plan to set up the first 2nd-life energy storage unit in Beijing, making use of retired BJEV electric car batteries. This project will serve as the basis for other types of cooperation in the future.

Gordon Gassmann, CEO of Mercedes-Benz Energy, creating a sustainable future through responsible use of resources is of paramount concern to the company.

“The extension of regenerative and thus high-fluctuation energy production is rapidly increasing worldwide. The tendency towards increasing distances between the site of energy production and the site of energy consumption also means huge challenges for today’s energy grids.

“This is creating wide-ranging opportunities for stationary energy storage systems worldwide. 2nd-life battery storage units are a very sensible supplement, as with the further utilisation of disused car batteries we are also making sustainable use of valuable raw materials,” said Gassman.

Ye Xiaohua, Deputy General Manager of BJEV, emphasized: “The rapid electrification of vehicles hastransformed vehicles from a traditional means of transport, to a new tool of energy management. BJEV is an expert in areas such as charging and battery swap infrastructure and battery 2nd-life usage. I believe our cooperation in energy management will bring long- term and stable benefits.”

As a subsidiary of Daimler AG, Mercedes-Benz Energy, which is based in Kamenz has been responsible for developing innovative energy storage solutions since 2016. These are based on the automotive battery technology, which is used in electric and hybrid vehicles from Mercedes-Benz and smart.

As a subsidiary of Daimler AG, Mercedes-Benz Energy, which is based in Kamenz has been responsible for developing innovative energy storage solutions since 2016. These are based on the automotive battery technology, which is used in electric and hybrid vehicles from Mercedes-Benz and smart.

The spectrum of large-scale storage applications by Mercedes- Benz Energy ranges from load peak compensation through black start (power system independent start up of the power plant) to uninterrupted power supply (USV).

The company’s focusis in particular on applications from the 2nd-life and replacement parts storage unit sector. Together with its partners, Daimler has already put three mass storage devices with a total energy of 40 MWh from car battery systems into the German grid.

Mercedes Benz Energy also furnished proof together with the transmission system operat or TenneT: automotive battery storage systems can take over tasks from large power stations and make a fundamental contribution towards grid stabilisation and system reconstruction following a power station outage.

The cooperation with the Chinese partner BJEV is now paving the way for the Daimler subsidiary to go abroad. With extensive tests and simulations, the Mercedes-Benz

Energy engineers will demonstrate in the coming months how electric automotive storage units will in future also be able to support the Chinese power grid efficiently and sustainably with regard to fluctuation and power outage management.

Beijing Electric Vehicle Co., Ltd. was established in 2009 by the BAIC Group as a development platform for New Energy Vehicles. With more than 420,000 battery electric vehicles on the market so far, BJEV is one of the leading manufacturers of all-electric vehicles in China.

Accordingly, their batteries form one of the largest pools worldwide and offer wide-ranging potential for 2nd-life applications in the area of stationary use.

In 2016, BAIC established Beijing Articore Battery to perform research into the utilization of 2nd-life batteries. Beijing Articore Battery is currently involved in the research of telecommunications base stations, highway renewable energy stations and mobile energy storage units. Research into micro-grid energy storage is also planned.

DuPont’s Tyvek air cargo covers offer unrivalled scientifically proven protection for temperature sensitive pharmaceuticals demanding extra care on air and while in transit from one point to another till safely delivered to their final destinations.

The global pharmaceutical industry continues to grow with rising demand across continents. And new innovative solutions to keep the therapeutic potency of these products while on air and in transit en route to their final destinations are evolving.

In the Middle East where harsh weather conditions require special attention and equipment in transporting certain products via air, land or sea, innovative products offering protection for sensitive pharmaceutical shipments like medicines, vaccines and other life sciences products continue to be utilized.

In the Middle East where harsh weather conditions require special attention and equipment in transporting certain products via air, land or sea, innovative products offering protection for sensitive pharmaceutical shipments like medicines, vaccines and other life sciences products continue to be utilized.

In the UAE, the pharmaceutical market sales have reportedly reached $3.1 billion in 2018 from only $2.4 billion in 2015. The increase was largely attributed to sales of prescription meds.

The UAE is estimated to have imported around Dh14.9 billion worth of products as part of pharmaceutical products (HS 30) from the world market in 2018, according to data from the UAE Federal Customs Authority.

But one of the biggest problems faced by shippers of pharmaceuticals relates to the need to keep shipments within the safe temperature bands required by prevailing legislation and best practice.

According to IATA, nearly 60% of temperature excursions occur during these ‘uncontrolled’ air- cargo stages of the distribution process.

Dr. Steve Brabbs, DuPont Global Technology Leader for Transport Protection, explained to Air Cargo Update in an email interview how Dupont’s Tyvek air cargo covers provide advanced protection to temperature sensitive pharmaceuticals.

He said the Tyvek range of thermal pallet covers are designed to address acknowledged weaknesses in the cold chain such as the problem of ‘ tarmac standing time ‘ where shipments of temperature sensitive goods are left standing in fluctuating ambient conditions during the airport loading, unloading and transit phases.

Combating threats

Brabbs said there are currently three different Tyvek thermal pallet covers available on the market, Tyvek Solar W10, Tyvek Solar W20 and Tyvek Xtreme W50 with further versions under development.

With temperature sensitive medicines the merchandise must be kept within carefully defined temperature envelopes during long- haul transportation to ensure they retain their therapeutic potency and consumers are not put at risk from dangerous or ineffective products.

In these cases, the unique reflective properties of Tyvek have been shown to keep shipments considerably cooler, by as much as 15 degrees Celsius, through the minimization of solar gain.

In the case of products, such as vaccines and insulin, which must be protected from cold temperatures, the insulated Tyvek Xtreme W50 version provides an excellent thermal buffer.

Strong and tear-resistant, Tyvek pallet covers also give excellent protection from tampering, rain, snow, wind, pests, debris and airborne contamination. The opaque white color of the covers provides additional security by shielding cargo from view and the smooth one-piece design readily provides a visual indication of irregular tampering.

Made from inherently breathable Tyvek fabric and materials all pallet covers can continuously evacuate water vapor to minimize condensation risks.

Tyvek vs. traditional covers

Essentially, Brabbs said Tyvek pallet covers are light, low bulk, thermally efficient and breathable. Alternative covers based on voluminous bubble wrap and multi bubble foil constructions are always going to be more difficult to store and more unwieldy to handle.

These air-bubble dependent covers are also liable to make a noticeable contribution to airfreight costs due to their volume adding to dimensional weight charges.

Instead of using a high bulk, easily damaged array of air bubbles for thermal insulation, the low-bulk Tyvek Xtreme W50 pallet cover employs a high thermal-efficiency fibrous layer.

This is not only much more thermally efficient than a bubble configuration of equivalent dimensions, but can also be unpacked and fitted in place in as little as 90 seconds.

Storage and transportation are made very easy due to the fact that such covers come multi-packed for very low storage space requirements, and they are typically around half the weight of a bubble foil equivalent. “ Most cargo covers ( thermal blankets, pallet covers) work by insulating the cargo from the outside environment, slowing the flow of heat from the outside to the cargo inside. We, instead, employ the extremely high reflectivity of Tyvek for sunlight, which is usually the main cause of heating on the airport tarmac, to throw that energy back into the environment so it never has a chance to penetrate to the precious goods under a Tyvek Cargo Cover. That means Tyvek Cargo Covers can be thinner, lighter, more flexible and easier to use than other pallet covers,” said Brabbs.

“ In fact, many packaging engineers’ first response when they touch a Tyvek Cargo Cover is that it is ‘too thin to be effective’, which leads them to believe that it is just a rain cover. But when they test Tyvek Cargo Covers, they find they work like magic, and are as good or better on the tarmacthan much thicker traditional pallet covers. But it’s not magic, it’s science,” he added.

It is worth noting that today’s increasingly multi modal freight haulage can be very demanding physically on a cargo cover. Handling damage is never completely avoidable, however – so if it does occur, it is important that it is visible and that minor detriment does not materially reduce the protection

being provided.

Unfortunately, damage to bubble- based materials is not always visible and yet can seriously compromise its thermal performance. It must be remembered that any air bubbles that are punctured will completely lose their insulative properties.

The thermal integrity of fibrous insulation, on the other hand, is not nearly so easily compromised when subject to minor handling abuse. Small penetrations effectively ‘self- heal’, while minor abrasions have no

detrimental effect on performance.

The natural permeability or ‘breath ability’ of all Tyvek pallet covers is another distinguishing feature. Perishable shipments are of ten exposed to fluctuating temperatures as they are moved between controlled and uncontrolled storage areas and between different transport modes.

These varying temperature conditions directly impact the levels of relative humidity and inevitably lead to condensation being formed as a consequence.

Recent comparative exercises between breath able and non breathable cargo cover materials have provided ample evidence of this condensation, potentially adverse, occurring with non-breathable materials during long distance air and truck transportation, even where overall temperature variations had been relatively modest. By contrast, the vapor-open material used in Tyvek breathable covers showed no signs of below-surface moisture

build-up.

Good for the freight industry

Recent reports indicate that many pharmaceutical products are now being transported to market by sea rather than air, not just for reasons of thermal consistency, as you might expect, but simply for reasons of cost.

Ocean freight are said to be 80 percent cheaper than airfreight.

With some airlines charging fuel surcharges based on chargeable weight rather than actual weight, shippers are starting to look more closely at the volumetric implications of their cargo protection.

The use of Tyvek pallet covers can make a worthwhile contribution to overall freight cost reduction, not just because of their high performance, but also because they exhibit low bulk and weight, and because they are easy to store and very quick to fit. For example, a standard euro-pallet Tyvek cover can be fitted or removed in as little as 60 seconds.

“Thin and lightweight Tyvek Cargo Covers pack small, so one box of them is typically equivalent to a whole pallet-load of traditional covers, in terms of the number of pallets of pharmaceuticals which can be protected with them.

That gives an immediate savings in warehouse costs. Much more significant is the reduction in labor and training costs, and increase in warehouse throughout. Their material and design make Tyvek Cargo Covers so easy to install, taking less than one minute to fit to a standard pallet, which is why warehouse managers love our covers,” said Brabbs.

“Lastly, many thicker thermal blankets add so much to the outer dimensions of each shipping pallet that the freight forwarder can no longer fit as many as normal on an airline pallet. That means more space is taken up in the aircraft hold, and that translates directly into higher freight charges. Tyvek Cargo Covers are so thin that the added size is not an issue, and even on our thickest Xtreme W50 covers, the structure is compressible so they don’t prevent loading the normal number of pallets together.”

Optimal cost saving solution

In a recent survey, 94 % o f respondents said that the finding of cost-effective temperature control services and solutions is one of their biggest challenges.

Like most things, it is not simply a case of considering the initial price; it is a question of considering the performance of a solution against both its initial purchase cost and its costs in use; in other words, its ‘whole life cost’.

Like most things, it is not simply a case of considering the initial price; it is a question of considering the performance of a solution against both its initial purchase cost and its costs in use; in other words, its ‘whole life cost’.

Only by considering all the associated costs and benefits, tangible and intangible, associated with a product over its life cycle can an informed choice be made concerning the optimum product or solution for a specific need.

“It depends, of course, on the sensitivity of the product and the threats experienced along the route. For most circumstances, Tyvek Solar W20 covers are the solution of choice, often with the optional pallet bases which limit ingress of air into the bottom,” explained Brabbs.

“In more extreme or high-risk situations, and especially when there is potential exposure to high and low temperatures on the route, Tyvek Xtreme W50 covers are the better choice. Many users have both in their arsenal and switch between them depending on the season or product. There are, of course, situations where we would not recommend Tyvek, nor any kind of cargo cover for that matter.”

A ‘passive’ cool chain element

At present a significant proportion of pharmaceuticals are transported with a ‘protection’ comprising a simple covering of stretch- wrap or bubble-wrap.

This is a wasteful exercise in itself since these materials are rarely re- useable and, even more seriously, they have been shown to contribute to un necessary temperatue deviations by causing serious heat gains through ‘greenhouse’ solar gain effects.

The elimination of the wastage that results will make a worthwhile contribution to minimizing unnecessary carbon emissions. The pallet cover solutions from DuPont also offer a superior strength to-weight ratio, which potentially can reduce energy use in transportation compared to heavier competitive products.

The use of very low weight materials results in less energy and resource consumption, and less material waste at the end of product life.

And that’s not all. As a ‘passive’ cool-chain element, these low-mass covers do not require any power or energy consuming preparation and, compared to alternative pallet wrappings and covers, they are more energy efficient than alternative 150 Micron films, bulky bubble wrap or corrugated cardboard protection and material, and, as a Grade 2 polymer, are 100% recyclable.

In 2017, DuPont announced a new courtesy recycling service for Tyvek Pallet Covers and at the moment the scheme is being rolled out across the US before being extended to other markets. The scheme is the latest step in the company’s commitment to sustainability and environmental stewardship and will ensure that all Tyvek customers have access to a satisfactory end-of-life solution.

The Tyvek recycling service supports the contention that with many thermal cargo covers, the efficient reclamation of single-use covers is kinder to the planet than attempting to juggle the numerous environmental deficits associated with re-usable covers.

The drawbacks of re-using covers include expensive, CO2-generating return logistics and the need to manage and finance rigorous product checking, repairing, cleaning, decontamination and testing regimes.

The Kempegowda International Airport, previously known as Bengaluru – BLR Airport – the gateway to the city continues to undergo major transformation.

The Bengaluru airport began operations in May 2008 and has significantly enhanced the regional and worldwide air connectivity of Bengaluru and Karnataka.

Bangalore, also known as Bengaluru, the capital city of Kartanaka State in India is seeing unprecedented growth in

aviation industry, thanks to its thriving IT industry.

Dubbed as the “Silicon Valley” of India, Bangalore is home to some of the biggest global tech companies, including the Indian Space Research Organization. It is the country’s second fastest- growing metropolis with more than 10 million people.

The Kempegowda International Airport, previously known as Bengaluru BLR Airport the gateway to the city continues to undergo major transformation.

The Kempegowda International Airport, previously known as Bengaluru BLR Airport the gateway to the city continues to undergo major transformation.

In 2018, it welcomed some 33.3 million passengers and the volumes are expected to grow in the coming years with India becoming the third largest aviation market in the world. Domestic traffic, the airport’s main growth driver, accounted for 28.82 million passengers, while international traffic grew +17.5% to 4.48 million.

Validation flights

On August 27, 2019, the second runway of the airport moved closer to a December 5 commercial opening with the successful completion of the validation flights.

The validation flights by SpiceJet, Air Asia and IndiGo, certified the aerodrome navigational aids and instrument procedures as determined by civil aviation regulations.

The second runway called the New South Parallel Runway allows the landing of Code F aircraft such as the massive Airbus A-380. The 255,000 sqm terminal, second runway, will cater to all international flights and Terminal 2 will have a capacity for over 45 million passengers, looking way into the future.

From April to July 2019, per Airports Authority of India (AAI), Bengaluru carried 16,65,234 international passengers up from 14,50,097 in 2018 registering a change of 14.8 per cent, while the airports of Delhi, Mumbai and Cochin showed negative growth.

Bengaluru carried 94,91,757 domestic passengers, up from 93,39,018 passengers during the period mentioned, a 1.6 per cent change. Hyderabad international airport is another airport which is doing well with regard to passenger and cargo movement.

Finances secured

Considering this growth, the expansion at Kempegowda International Airport by Bangalore International Airport Limited (BIAL), its operator, is becoming more urgent.

It is said to be one of the largest infrastructure projects in the country. BIAL is undertaking a massive Rs. 13,352 crore (USD1.8 billion) capital program to cater to the demands of a civil aviation market that has been

growing at a blistering pace of 25% year on year for the last three years.

The current capital development program includes a new terminal, a second runway, massive expansion to the access roads and internal road infrastructure, utilities as well as a new multi-modal transport hub.

BIAL has raised Rs. 10,206 crores (USD1.4 billion) through a syndicate of banks, including State Bank of India and Axis Bank, with the project to be funded in a debt-equity ratio of 80:20. The debt would be repaid over

a period of 10 years with a one-year moratorium post completion of the project.

The Managing Director and CEO of BIAL, Hari Marar, said: “The second terminal – T2 – is our dedication to this beautiful city of Bengaluru. Designed as a reflection of this City, T2 will be founded on 4 pillars: technological leadership, being a terminal in a garden, environmental and ecological stewardship and a celebration of Karnataka’s rich heritage and culture.

“Of course, it goes without saying that all this will be centred on the most important element – the needs of our customers. BIAL worked with some of the finest global minds on the design and planning of this Terminal. While T2 is designed to be an iconic terminal one that Bengaluru can truly be proud of – it will be built at the most affordable cost and in the most responsible manner.

“The Terminal will be world-class in all respects – starting from its design, the processes, the people who

“The Terminal will be world-class in all respects – starting from its design, the processes, the people who

manage it, the sustainable practices it embraces and the performance it achieves.”

Marar pointed out the BLR Airport has evolved as the gateway to South India over the past 10 years and its next phase of expansion positions the airport as the main entry point to a new India.

“Once ready, the airport will offer passengers seamless and delightful experiences, powered by cutting edge technology,” he added. Connecting people and cargo Bhaskar Anand Rao, Chief Financial Officer, BIAL, said the project would be a boost to the economy. “ Phase 2 of Kempe gowda International Airport, Bengaluru will provide a huge boost to the connectivity of people and goods of the state and provide the much needed capacity that a growing city like Bengaluru richly deserves. Once operational, the airport will create more opportunities for businesses at the Airport and fuel the economic growth of the region and country,” said Rao.

“Our aim has been to ensure that not only should we deliver an iconic asset of which the people can be truly proud, but also set benchmarks in the way such project is delivered – at a cost that is affordable and to the highest standards of corporate governance,” he added.

Tom Shimmin, Chief Project Officer, BIAL, said once the airport’s Terminal 2 is completed, it will substantially increase its overall capacity.

“With the use of a combination of the latest in construction technology and natural material, this Terminal will establish a new vision for sustainable growth. The new passenger terminal will cater to the specific needs of the Airport’s spectrum of users and provide a seamless travel experience. This will help the B L R Airport remain competitive and stay ahead of the growth in passenger demand,” he said.

Sustainability remains a key pillar as operations at BLR Airport are conducted in a very responsible manner to ensure integrity of economic viability, operational excellence and conservation of natural resources.

Acclaimed for its world-class passenger-friendly amenities and services, the BLR Airport — operated by BIAL has implemented various landmark initiatives with major focus on energy saving, water conservation, waste management and pollution control measures.

With a clearly defined Sustainability Policy in place, BIAL is focused on making substantial contributions to sustainable development.

“At BIAL we are committed to achieving excellence in environment sustainability. Our efforts are focused on care fully managing our environmental responsibilities. In our attempt to be a role model for sustainable progress, we have made along term commitment to sustainability and community engagement that will effect a change in culture,” Marar noted.

The airport is also making optimal use of natural light with minimum reliance on artificial illumination. BIAL’s other energy efficient initiatives include installation of solar street lighting ; solar powered security cabins; a solar water heating system for the cafeterias.

It is India’s first Greenfield airport built on public-private partnership model where private promoters hold 74 percent (Fairfax: 54 % and Siemens Projects Ventures: 20 %) stake, while the government holds the remaining 26 % (Karnataka State Industrial & Infrastructure Development Corporation Limited 13% and Airports Authority of India 13 %).

The Bengaluru airport began operations in May 2008 and has significantly enhanced the regional and worldwide air connectivity of Bengaluru and Karnataka. It is currently the busiest airport in South India and the third largest in India, after Delhi and Mumbai.

Bordering the Russian Federation on the north, Iran on the south, the Caspian Sea on the east, and Georgia on the west, Azerbaijan has the geographic advantage of having the shortest distance to connect Europe to Asia and beyond with ample resources to finance businesses to realize economic gains from its unique geopolitical landscape.

With abundant deposits of oil and gas, Azerbaijan, once part of the Union of Soviet Socialist Republics, ( USSR ) quickly established its own oil-based economy following the collapse of the communist regime in 1991.

With abundant deposits of oil and gas, Azerbaijan, once part of the Union of Soviet Socialist Republics, ( USSR ) quickly established its own oil-based economy following the collapse of the communist regime in 1991.

But the volatile global economy had taken its toll on Azerbaijan’s oil-dependent economy, leaving it vulnerable to external shocks, peaking between 2014 -2016,

devaluing the country’s currency by as much as – 31 percent exacerbated by record high in flation rates, according to reports.

Azerbaijan had since recovered from its economic crisis, posting moderate growth of + 1 . 4 % increase on real GDP in 2018 and +2.4% year-on-year during the first half of 2019, according to the latest report of global research market leader Euler Hermes.

“Increased gas exports from the Shahdeniz Phase II field, thanks to the Southern Gas Corridor pipeline becoming operational, as well as strengthening domestic demand on the back of lower inflation and interest rates, have lifted economic growth to +2.4% y/y in H1 2019. We expect this moderate dynamic to continue and forecast full-year GDP growth of about +2.5% in both 2019 and 2020. However, global uncertainties, including the rise in trade tensions and potentially lower oil prices, pose downside risks to this forecast,” Euler Hermes said in its report.

“Inflation has picked up slightly to 3% y/y in June 2019 but we expect it to remain in check in the near future, averaging about 3% in 2019 as a whole and 3.5% in 2020. However, the potential impact of global uncertainties on emerging market currencies in general, as well as ongoing domestic banking sector vulnerabilities, pose upside risks to this forecast,” it added.

Caspian’s leading cargo airline

Uniquely positioned to undertake projects diversifying its oil based economy while promoting growth in Central Asia, Azerbaijan had long envisioned to grow its foothold in the Caspian region through the development of its logistics and aviation sectors.

The state-owned Silkway West Airlines—one of 23 businesses under Azerbaijan’s Silk Way Group formed in 2006 continues to thread the path of becoming Central Asia’s leading cargo airline, growing its route network to more than 50 destinations.

The state-owned Silkway West Airlines—one of 23 businesses under Azerbaijan’s Silk Way Group formed in 2006 continues to thread the path of becoming Central Asia’s leading cargo airline, growing its route network to more than 50 destinations.

Records from the State Statistical Committee of the Republic of Azerbaijan showed from 21,000 tons of air cargo in 1990, the country’s air freight industry hauled 208,000 tons in 2018, and signs for more growth are in the horizon as demand for e-Commerce in the region rises.

In late 2018, Silk way We st Airlines received its new Boeing 747-400 plane, increasing its total fleet of 747 freighters to 10. The move is part of the airline’s long- term goal to further grow its scheduled network while enhancing options for charter flights among its growing clienteles.

This year, the cargo carrier made major leadership roles in its key markets—the United States and Asia-Pacific—positioning itself to aggressively compete in these growing regions.

On September 27, the airline launched its long awaited freighter operation from Oslo Gardermoen Airport connecting

the Norwegian salmon industry to its hub in Baku.

“We are excited to offer the Norwegian Seafood industry increased connectivities through our Global Aircargo Hub in Baku.

Silkway has been flying Norwegian Seafood for many years through other European gateways, and we are now very pleased to finally add Oslo to our global network,” Silkway Commercial Director Europe Riad Fataliyev said in a statement.

Silkway has been flying Norwegian Seafood for many years through other European gateways, and we are now very pleased to finally add Oslo to our global network,” Silkway Commercial Director Europe Riad Fataliyev said in a statement.

Silkway says it will use a B747- 400F for the Oslo Friday flight connecting the whole Far East via Baku where its state-of-the-art facilities for air cargo are located.

Apart from investing on new planes to spruce up operations of Silkway WestAirlines, the Azerbaijan government also vastly expanded the carrier’s cargo facilities with sophisticated cold storage and a modern general cargo terminal at the Heydar Aliyev International Airport in Baku.

Eurasia Trans-Hub

Azerbaijan President Ilham Aliyev said the country will continue to invest in logistics and transportation industries as part of long term plans to diversify Azerbaijan’s economy and position itself as the trans-hub in Eurasia.

Part of this is to export gas to Azerbaijan’s neighboring countries through pipelines connecting the country to Turkey and the European markets.

In 2013, Turkey and Azerbaijan signed an initiative agreeing to link through the South Caucasus Gas Pipeline project the Turkish border to the south of Italy to deliver the Azerbaijani gas to its European markets.

In 2013, Turkey and Azerbaijan signed an initiative agreeing to link through the South Caucasus Gas Pipeline project the Turkish border to the south of Italy to deliver the Azerbaijani gas to its European markets.

This project, also known as the “Southern Gas Corridor”, is expected to be fully completed by 2020, enabling Azerbaijan to reposition itself as a major gas supplier in Europe.

In a July 2019 meeting with EU President Donald Tusk, Aliyev expressed hope Azerbaijan’s investments on logistics and transportation sectors would strengthen its ties with Europe politically, socially and economically.

Tusk, for his part said, the Southern Gas Corridor “quite literally connects us” referring to Azerbaijan and Europe, saying, “This positive momentum should bring our partnership to a higher level, directly benefit all our people, and accompany Azerbaijan’s own reform processes and economic diversification.”

Apart from investing on major gas pipelines, Azerbaijan is also building the Baku-Tbilisi-Kars railway which links the Soviet-era rail systems of Azerbaijan to Georgia and Turkey and eventually, to the rest of Europe with projected peak capacity of 17 million tons of cargo per year, once fully operational.

The project’s first phase will enable the railway to handle million passengers and 6.5 million tons of cargo.

And there’s also the Alat Port, opening up a new transit trade route between Europe, Central Asia, South Asia and the East and allowing for multi modal North / South and East/West transit which has rail ferries that can transport 52 train cars at a time. About 4 million tons of cargo (oil excluded) were handled at Alat Port in 2018, the government said.

The government vows to continue transforming Azerbaijan into an international transport hub. And this process includes the development of the shortest multi modal land corridors between China and the EU; creation of the North South Transport Corridor; attraction of transit cargo as part of the Great Silk Road; digitalization of the Great Silk Road through Azerbaijan`s Digital Transport Network and TA S I M projects, and; commissioning of new international airports & construction of new roads across the country.

Boeing Forecast: Russia and Central Asia-Europe air cargo market to grow 3.4% annually over the next 20 years

The Russia and Central Asia market accounts for approximately 1.4 percent of the world’s total air cargo traffic in ton- kilometers and 2.4 percent in tonnage.

Air trade originating in or destined to Russia and Central Asia was estimated at 1.3 million tons in 2017, based on the region’s airport statistics. Growth averaged 2.7 percent from 2007 to 2017, based on tonnage handled at airports.

Fueled by high oil and gas prices, Russia and Central Asia air trade expanded 50 percent after 2009, peaking at 1.3 million tons in 2011. Contraction in the region’s air cargo volumes gathered pace in 2014 and 2015, as investment in extractive in dustries slowed, consumer spending fell, and trade sanctions were imposed on Russia for its support of the conflict in Ukraine.

Fueled by high oil and gas prices, Russia and Central Asia air trade expanded 50 percent after 2009, peaking at 1.3 million tons in 2011. Contraction in the region’s air cargo volumes gathered pace in 2014 and 2015, as investment in extractive in dustries slowed, consumer spending fell, and trade sanctions were imposed on Russia for its support of the conflict in Ukraine.

Regional air trade expanded 10 percent and 14 percent in 2016 and 2017, respectively, as the world economy recovered , commodity prices stabilized, and Russia reoriented much of its international air trade toward East Asia rather than Europe.

The Russia and Central Asia–Europe air cargo market will grow at an average annual rate of 3.4 percent for the next two decades.

Russia and Central Asia air exports to Europe will grow at a rate of 3.6 percent to reach 107,000 tons by 2037. European demand for Russia- produced specialty chemicals and industrial metals, specialized scientific equipment, and aerospace goods will bolster growth for the forecast period.

Pro-business legislation and an improved foreign investment climate could promote an export-driven economy for a wide array of manufactured and semi manufactured goods, leading to the high- growth projection. Conversely, continuing regional conflicts, laws and regulations adverse to new businesses, or renationalization of industries would impede air trade growth, leading to the low-growth projection.

ESCALATING trade tensions and a slowing global economy have led World Trade Organization (WTO) economists to sharply downgrade their forecasts for trade growth in 2019 and 2020.

The news is a major blow to air cargo bosses hoping for an upturn in shipments next year, writes Thelma Etim.

Global trade volumes are now expected to rise by only 1.2 percent in 2019, substantially lower than the 2.6 percent growth forecast in April this year, reveals an official statement from the WTO.

The projected increase in 2020 is now 2.7 per cent, down from 3.0 percent previously. WTO economists caution that “downside risks remain high and that the 2020 projection depends on a return to more normal trade relations.”

Roberto Azevêdo, director-general of the World Trade Organisation, fears that “job creation may also be hampered as firms employ fewer workers to produce goods and services for export.

“The darkening outlook for trade is discouraging but not unexpected. Beyond their direct effects, trade conflicts heighten uncertainty, which is leading some businesses to delay the productivity-enhancing investments that are essential to raising living standards,” Azevêdo observes.

“Resolving trade disagreements would allow WTO members to avoid such costs,” he asserts.

‘The multilateral trading system remains the most important global forum for settling differences and providing solutions for the challenges of the 21st-century global economy. Members should work together in a spirit of cooperation to reform the WTO and make it even stronger and more effective,” he declares.

More tariffs and resulting retaliation could produce a ‘destructive cycle of recrimination,’ the international body also warns.

“A sharper slowing of the global economy could produce an even bigger downturn in trade. Finally, a disorderly Brexit [in the UK] could have a significant regional impact, mostly confined to Europe,” adds the statement.

AIT Worldwide Logistics’ Life Sciences Control Tower has received Good Distribution Practice certification from inspector SGS.

The GDP certificate requires pharmaceutical handlers to meet World Health Organization standards for safety and security.

It is not a global requirement but European Union companies and their logistics partners must comply with GDP.

The life science control tower in Itasca, Illinois underwent several documents, process and procedure audit to obtain certification, including a two-day onsite assessment and a live product recall drill.

SGS also reviewed AIT’s vendors and suppliers, as well as physical inspections of the control tower’s containers and packaging, sanitary conditions, security and temperature control variations.

William Freidal, sales director of AIT Life Sciences says: “In an increasingly complex industry, GDP certification elevates our global offering. It not only affirms our commitment as a premium pharmaceuticals and life sciences logistics provider, it underlines our dedication to security and quality across the board.”

Aaron Ambrite, global compliance director of AIT adds: “The certification process was all-encompassing to ensure that AIT’s cold-chain procedures meet WHO standards and provide customers with a secure, safe, and efficient supply chain for pharmaceutical cargo. We were well positioned going into the audit, and it provided an opportunity for the control tower to enhance and improve upon already existing procedures.”

American Airlines Cargo welcomed a special guest on a Buenos Aires – Dallas flight, Sandra the orangutan who has human rights.

The 33-year-old orangutan has spent her life in captivity, born in Germany before moving to a zoo in Argentina 25 years ago.

After protests to provide Sandra with better living conditions, she was granted human rights for a non-human by Argentine judge Elena Liberatori to aid her relocation to a primate sanctuary.

Sandra flew from Buenos Aires Ezeiza International Airport to Dallas Fort Worth International Airport on a Boeing 787-8 for the 11-hour flight.

Airline team members volunteered their time to assist Sandra on the morning of 27 September, and in accordance with federal labour laws and centre for disease control procedures, they were on hand to ensure best-in-class customer experience.

Upon arrival, Sandra was safely loaded into a waiting van to travel to Sedgwick County zoo in Kansas, where she will complete quarantine before moving to the Center for Great Apes in Florida.

Sandra travelled in a specially designed container to which she had grown accustomed and would willingly enter ahead of the flight.

The cargo operations and sales teams in Dallas and Buenos Aires worked closely with Sandra’s handlers and airport personnel to confirm her journey would be the best option.

David Vance, vice president operations for American Airlines Cargo says: “It was an honour to provide our services to aid in Sandra’s relocation and eventual new home in a more suitable environment. Our teams worked hard and quickly to ensure everything ran smoothly, and we look forward to following Sandra’s story.”

Industry veteran Robert Van de Weg, has joined Paris-based ECS Group to help with its revolutionary transformation. The KLM Cargo, Atlas Air, Cargolux and, most recently, Volga Dnepr Group veteran says, “ECS Group represents the future of our industry – reinventing it and driving it forward. Joining ECS Group means making a contribution to the revival of this industry, and it means putting in place a clear and ambitious strategy, supported by digital technology and business Intelligence tools that can help our airline clients move forward. That’s why I accepted this position as CCO and it’s probably the most exciting challenge of my career.”

Adrien Thominet, ECS Group CEO, said: “Robert Van de Weg is the ideal coach to help our teams reach new heights. With him at the helm of our commercial strategy, we can confidently say that we’re ready for this new chapter in ECS Group’s history.”

UPS will invest $750 million at its Worldport base in Louisville, Kentucky including the construction of a $220 million aircraft maintenance hangar.

The 262,000 square foot hangar will be able to accommodate two Boeing 747-8 Freighters and will be built on leased land at the northwest corner of the airport, on the opposite end of the property from the Worldport campus.

Permitting and construction will begin in 2020 is expected to be completed by 2022.

UPS’s Next Day Air volumes are growing rapidly, and healthcare, e-commerce and small business customers are demanding faster delivery times, so UPS will add 50 new, converted and leased 747-8s and 767s to the fleet by 2022.

Over 15 years, UPS expects to spend $750 million on construction projects and create over 1,000 jobs including pilots, aircraft mechanics and support staff.

Other infrastructure projects will include ramp and taxiway improvements, and renovated offices.

Brendan Canavan, president of UPS Airlines says: “We are grateful for public sector support with these incentives. They are a win-win, allowing UPS to expand in Kentucky while increasing tax revenues and creating jobs in the city and throughout the state.”

Kentucky Governor Matt Bevin says: “Businesses and consumers now operate at a faster pace than ever, and that is reflected in their shipping and distribution needs. It is the mark of a great company that UPS has quickly responded to customer demand by expanding its air cargo fleet here in Louisville.”