Quest for a 'connected cargo supply chain'

“In order to transform the industry, it needs to address key challenges and converge, bringing the distribution and transportation process together. The entire cargo industry should adopt centralized datasets, that are updated in real-time using Internet of Things (IoT), hastening processes and allowing buyers and sellers to access up to date and accurate information.”

The Internet of Things (IoT) is the latest buzzword in the air cargo industry often heard from cargo experts when they talk about digital innovations. IoT has the potential to revolutionize the connectivity of the supply chain by tightening efficiency in operations and in ways that were never possible before.

According to studies, the global Internet of Things (IoT) market size was valued at $212.1 billion and is expected to witness a growth of 25.68% from 2019 – 2026, reaching $1319.08 billion by 2026.

Approximately 87% of supply chain executives say they plan to increase their use of IoT over the coming months/years where around $6.8 trillion worth of goods are shipped annually. There is too much at stake not to adopt the latest technology- even if the expense seems high. An inability or unwillingness to embrace digital innovations end up costing more in the long run.

In an email interview with Air Cargo Update, Niranjan Navaratnarajah, cargo industry director, Unisys Asia Pacific explains why IoT is a necessary adoption in the air cargo industry for modernizing fast shipment processes.

Distribution process

The air cargo business is a very important business for the global air transport market and one of the main barriers to its modernization has been the over reliance on paper, stakeholders processing data from data islands which may well already be out of date, and duplication of data entry creating more opportunities for errors.

Navaratnarajah says, “In order to transform the industry, it needs to address key challenges and converge and bring the distribution and transportation process together. The entire cargo industry should adopt centralized datasets, that are updated in real-time using mobile devices, automation and Internet of Things ( Io T) hastening processes and allowing buyers and sellers to access up to date and accurate information.

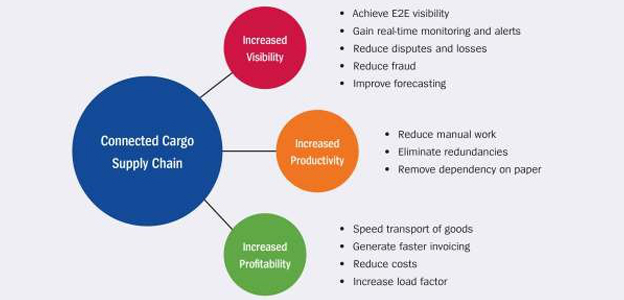

“Devices need to communicate directly with systems to improve accuracy and make real time data available to operators for swifter action on shipments. Devices need to monitor special and valuable cargo and alert operators if corrective action is required. This must be done while also protecting and securing data ie ensuring the right data is available to the r ight operators only. This ‘connected cargo supply chain’ offers customers greater visibility, certainty and satisfaction with faster delivery to customers’ door”.

Millions of cargo shipments move around the world every single day. Some are shipping internationally and some domestically. These shipments have one thing in common: delivery without delay.

And when it is not delivered as planned, it can create problems both for the shipper and the consignee. It is the objective of the freight forwarder to work with you to make the shipment as efficient as possible.

“The biggest problem is shipment ‘idle’ time – when it is sitting on the ground, not moving to its destination. This is primarily due to over reliance on paper; lack of up- to- date information to process shipments, data islands and stakeholders recreating the same data multiple times resulting in errors. Warehouses should not be storage locations – they should be highly efficient smart ware houses with very high throughput.

“A large proportion of delays is attributed to ground based processing of cargo so that’s where the collaboration, connectivity and optimization should be implemented to have the greatest impact on shortening processing times. Reducing this will improve the customer experience, optimize asset utilization, improve security and reduce unnecessary storage costs,” Navaratnarajah explained.

Order fulfillment and quick delivery is critical to customer experience. If customers are satisfied and delighted, they will order more frequently, thus, driving faster order cycle times.

Conversely, some organizations believe shorter order cycle times can trigger faster order fulfillment as the customer will order more often if their fulfillment time is shorter.

“At Unisys, we believe order fulfillment time needs to continuously improve in line with increasing customer expectations as the new age customer wants their goods to be delivered ever faster. To achieve this the industry must continuously improve processing times and collaborate across the transportation industry to integrate and process higher volumes faster to shorten the overall transport and fulfillment times,” said Navaratnarajah.

Reduction in time cycle

In a secure connected cargo supply chain, information flows automatically and mobile devices, wearables, sensors and drones enable staff to process shipments on the spot updating data in real- time; weigh bridges automatically exchange data with systems preventing data errors and fraud; and IoT enabled sensors on shipments proactively alert cargo systems and staff if a shipment has been left behind, in the wrong location, or is distressed.

Centralized data and reuse of most common data is pivotal for shorter cycle times. Ultimately using these means to process shipment quicker will improve the customer experience. Some players are already doing this, but an industry-wide approach is needed to transform the whole supply chain to shorten the order fulfillment times.

“Buyers and sellers must move their business to online ecommerce platforms – which can be their own in-house platform or one that spans a community of forwarders, airlines, general sales agents and handlers, such as Unisys Digi-Portal. Such real- time platforms enable buyers to interact with automated real-time inventory and not rely on stored data,” Navaratnarajah explained.

“Buyers and sellers must move their business to online ecommerce platforms – which can be their own in-house platform or one that spans a community of forwarders, airlines, general sales agents and handlers, such as Unisys Digi-Portal. Such real- time platforms enable buyers to interact with automated real-time inventory and not rely on stored data,” Navaratnarajah explained.

“In addition, growth in consumer online purchases has not only increased small parcel deliveries, it has created an expectation that customers can easily track their deliveries. Real-time data, used across the supply chain, enables greater visibility and trace ability of shipments. With 60 . 8 percent penetration of e-AWB in the cargo globally, the industry is well poised to move to centralized e-AWB based centralized datasets in the next 12-18 months. And as 8 of the top 10 countries of origin for e-AWBs are in Asia, and five of the six top airports of origin are Asian, we can expect this region, the ‘world’s manufacturing bowl’, will lead the way,” he added.

Moreover, artificial intelligence (AI), IoT and predictive analytics can improve visibility, efficiency and security. As cargo records are more accessible and accurate their information can be used to better manage, process and track cargo, particularly sensitive items like medicine or food, which must be stored at certain temperatures.

Moreover, artificial intelligence (AI), IoT and predictive analytics can improve visibility, efficiency and security. As cargo records are more accessible and accurate their information can be used to better manage, process and track cargo, particularly sensitive items like medicine or food, which must be stored at certain temperatures.

Sensors can record shipment characteristics and alert operators when shipments approach distress levels so that they can take action to prevent mishap and the resulting claims.

“AI powered by predictive analytics can help freight forwarders to ingest and analyze data in real-time, helping to determine if sensitive shipments require specific attention or if the shipping conditions need to be modified.

Predictive analytics can also generate data to enable airlines to better plan their routes, avoid inclement weather and validate the security of shipments. Mobile devices and smart phones will provide real- time visibility into shipments to assist to process goods faster, locate misplaced items, which can greatly impact the customer experience.

Connected devices will share data across and avoid the need to use paper and help process goods faster. Integrated with such targeting tools, the connected cargo approach would improve the clearance and tracking of shipments from loading to arrival.

“Also, moving to a digital data- based cargo supply chain enables the integration of advanced security information and event management (SIEM) tools, such as the Unisys Stealth® platform with automated Dynamic Isolation, to protect customer information and shipment data from being accessed or modified by unauthorized parties, preventing data theft and cargo fraud”.

Is air freight a challenging market?

Adaptation of technology is disparate across the stakeholders that results in multiple data creation and data islands. Supply chains are often broken due to the limitations of the lowest common denominators.

Regulators demand more real time knowledge of the goods that are being imported and expect airlines to report accurately using data from source.

Regulators are holding airlines responsible to the data that are being filed. They are also demanding that airlines use common data sets such as harmonized codes to report goods for approval.

Acceptance and delivery of goods at customers’ door are done through multiple means and without digital signatures and not knowing the condition of goods. Claims are raised and settled with no evidence of the condition of goods at handover.

Airlines often face bad debts and write offs due to insufficient credit control. At the end of the spectrum operators aren’t privy to detailed analytics and visualizations.

“Being able to capture real-time data by securely integrating mobility, IoT and data automation to make updates on the spot and exchange information faster will reduce the time that cargo is left on the ground. The Cargo and logistics industry is laden with manual activity and is paper driven, information sharing is limited and stakeholders have to create and process their own data multiple times often delaying access to information to process goods faster. I o T with devices and connectivity will significantly change the way data and access to real time data is used to process cargo shipments. Operators will be using real time data and customers will have access to up-to-date knowledge of their shipment movement. This will significantly alter the transportation landscape to process goods faster to shorten the order fulfillment cycle.”

Unisys has more than 55 years of experience providing innovative IT solutions to the travel and transportation industry. Digistics is a holistic and integrated modular air cargo software logistics solution that allows carriers to streamline freight management and improve their operational efficiencies.

“ We provide independent customer buying and selling portals, app-based mobility solutions for the warehouse and door delivery services, device integration and data sharing, sensors that record shipment behavior through the journey including alerting during distress, piece level tracking including pharmaceutical t racking, safe transport of pets are some of the solutions Unisys provides to the industry.

“The Digi-Connect module uses a common platform to collaborate with stake holders for information exchange through open APIs. Underpinning all of these is an advance analytics and visualization layers that provides advance views of the trends, behaviors and predictions.”

Are smart warehouses a reality?

According to Navaratnarajah, smart warehouses indeed are a reality, “In 2017 we predicted that to meet the growing demand for small parcel deliveries and e-Commerce boom, warehouses will transform from a storage location, to a dynamic facility using Io T and voice artificial Intelligence (voice AI) enabling faster processing of more shipments to generate a higher return on the real- estate investment.”

Just as connected wearable devices such as smart watches are becoming mainstream in the consumer world, IoT-based technology will create the ‘smart warehouse’ of the future.

Drones and robots will augment human activity and perform high volume tasks that were not done in the past. Device communication is central to data sharing and speeding processing in the warehouse. Warehouses will no longer be storage locations but processing centers that will have high throughput.

“Such efficiency will attract more cargo from less efficient locations and develop transshipment hubs. Recent innovations such as smart glasses used to display information triggered by a barcode or QR code on a container will be taken to a new level by incorporating scanners to automatically capture and input information into the warehouse system, and integrating voice AI to initiate actions,” he concludes.

Similar technology is already used in digital assistants such as Siri, Cortana or Amazon Echo. Unisys expects cargo operators to invest in converting machine commands to voice within the next three years.

Future global t rade will be significantly powered by online e- Commerce boom that will demand more transport by air, warehouses will be at the epic center of enabling this. Warehouses will have to deliver the highest efficiency if this is to be sustained. Highly automated and connected smart warehouses will, thus, be essential to augment this and help the cargo industry grow.