Jettainer: The global ULD expert protecting cargo in the sky for over 20 years

“Our experts live and breathe ULD management, and we have the suitable digital solutions to meet even highest customer requirements with our services at all times and offer significant added value. We want to growth further on the path we have embarked on in the long term and, with an openness to innovation, continue to convince with leading services in the future.” – Dr. Jan-Wilhelm Breithaupt, Jettainer CEO

In just about two decades time, Jettainer, a wholly owned subsidiary of Lufthansa Cargo AG, has emerged as a global leader operating one of the world’s most efficient unit load devices fleet.

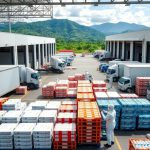

It has over 100,000 ULDs in 500 locations worldwide and is constantly enhancing its operations to meet the challenging demands of the air cargo sector, whether it is handling dangerous goods, live animals, pharma and what-have-you?

Jettainer is truly an industry leader, deploying a unique combination of dedicated teams and leading IT solutions, big data and artificial intelligence.

The CEO of Jettainer, Dr. Jan-Wilhelm Breithaupt, who is new to the company but has known the business from a customer perspective for many years as an experienced airfreight expert gives Air Cargo Update an in-depth insight in this Q&A into what Jettainer is doing to stay ahead of the competition.

Dr. Jan-Wilhelm Breithaupt holds a doctorate in production logistics and has been driving industry-wide digital transformation projects and process improvement initiatives for more than 20 years. He held various positions within the Lufthansa Group and was most recently responsible for global customer service and handling management at Lufthansa Cargo before taking on the role as Jettainer CEO. Here’s our interview.

With encouraging growth of global air cargo in 2024, how is the ULD segment coping with this demand?

The aviation industry is on the rise, and with it the need for ULDs and their management. Especially in the cargo sector, demand is increasing. Our leasing service lease&fly was almost completely booked out at times. We are also experiencing the effects of growth with our existing customers, for which we are stocking up the ULD fleets. By the end of the year, we will be managing around 110,000 ULDs for our customers worldwide.

Our highly efficient management is therefore also becoming even more interesting for new customers. With Jettainer, the available ULDs of an airline can be utilized more efficiently, so that significant growth from the existing ULD fleet is possible without any need for additional units.

As e-commerce is witnessing exponential growth, tell us how ULDs have been configured to deliver safely and in a day?

E-commerce is driving air cargo and has a considerable influence on the ULD business. Demand for ULDs is increasing and the requirements for handling speed and tracking have also grown. The entire industry must adapt to this. As part of this, efficient ULD management is also becoming more important.

Another aspect is that for safety reasons, the demand for fire-resistant containers is also increasing. Here, too, we responded at an early stage. Since last year, we have been offering the first fully certified fire-resistant container. The new container is the result of close cooperation with Satco Inc., a renowned manufacturer with decades of technological expertise and quality standards. We also provide a range of other fire-resistant containers and fire containment covers for pallets that have been successfully tested.

With 20-year forecasts of 40,000 new airplanes, what does that translate for ULDs?

ULDs are an elementary part of aviation. Whether for baggage or cargo, they are needed for every containerized aircraft flight. We are prepared for further growth and are closely monitoring the market. Thus, we can react flexibly to the needs of our existing and upcoming new customers at all times. Thanks to our pool of historical data and our sophisticated forecasting tool, we are able to plan ahead and anticipate.

What kind of innovations can we expect in ULDs?

The aim is to lighten the ULD without compromising its robustness. We are always interested in new developments and continuously exchange with manufacturers. In addition to fire-resistant containers, for example, we also provide nets for pallets made from sustainable bio-based materials, from our long-standing partner AmSafe Bridport. Around 60 percent lighter than conventional polyester options, they reduce fuel consumption, cutting costs and greenhouse gas emissions in international air transport.

Class-D fire-resistant containers for the transport of lithium batteries are another topic. IATA is working on the development of a standard for this, and we are monitoring the situation very closely to ensure that we can offer our customers optimum solutions.

In addition to the units themselves, we are also striving to make the ULDs journey even more transparent. There are still gaps that we want to fill in order to achieve further improvements and achieve an even higher level of efficiency for our customers, especially where units leave the airports. Digital solutions and better data transfer between all parties involved are key factors.

ONE Record data sharing standard offers completely new possibilities to do this. This is why we are preparing to adopt the IATA ONE Record standard for all areas of ULD management. By adding additional data from the handling process or the truck operators, we will enrich our knowledge base with more information. In doing so, it will allow us to provide our customers with additional valuable information.

Ultimately, ONERecord, JettWare and our digital twins will be the home of all ULD related data. Innovation will come from connecting new innovative sources, such as tracking devices, automatic loading systems, e.g., robots loading and unloading baggage, airport baggage handling systems, and many more. Based on the data gained from these sources, new AI modelling and prediction algorithms can be applied to furthermore reduce life-cycle cost and improve utilization of ULDs.

Sustainability is key in the aviation sector, take us through the sustainability efforts in ULDs?

Sustainability is a driver for change and innovation in the industry. The efficiency of our ULD management service, for example, which ensures that airlines can operate with fewer ULDs and that these are managed in an efficient way to avoid empty positioning flights.

Increasing utilization and efficiency of ULDs allows us to use considerably less material and equipment. This also reduces emissions, as aluminum production requires large amounts of energy.

Of course, the units used also have a major impact. Together with our customer Lufthansa, we played a key role in the development of the first lightweight containers, which were launched already in 2009. We are using modern lightweight materials, not only for the ULDs but also for straps and nets, to save both weight and CO2.

For example, we use the environmentally friendly Pallet Net Zero pallet nets from our long-standing partner AmSafe Bridport. These specially developed nets made from sustainable bio-based materials are the lightest on the market. They are around 60 percent lighter than conventional polyester versions and reduce fuel consumption, costs and greenhouse gas emissions.

For airlines that are not our customers, we offer skypooling, a free online portal for balancing excess or short stocks of ULDs.

Reports indicate that mishandled ULDs are the biggest cause of aircraft ground damage, costing the industry $300 million annually in repairs, can you explain this ‘avoidable’ factor?

ULDs are an important and valuable resource. There should be more awareness in the industry that ULDs are aircraft equipment providing safety cargo restraint in flight. The issue of damage on ULDs is very serious and causes high costs for the industry every year. Furthermore, ULD damage is also relevant to flight safety and workplace safety. We therefore work closely with manufacturers, MROs, and regulators to design ULDs in such a way that the risk of damage is minimized.

To decide whether a ULD is still serviceable in the case of a small damage, we provide our customers with special measuring cards that can be used to determine whether a ULD can still be used or needs to be repaired.

And above all, we never tire of raising awareness of the correct handling of ULDs. With special courses, we train several thousand ground handling employees worldwide in correct storage as well as proper handling of the units. Incorrect handling of ULDs, such as placing and loading them directly on the warehouse floor, is unfortunately a common but avoidable practice among airlines and freight forwarders, which we are addressing.

And we are also actively engaged in ULD Care, the trade association for ULD owners, operators and associated activities, and support all activities that promote the appropriate handling of ULDs.

Cargo shifting during flights is said to be ‘quite common’ event, is there something wrong with regard to ULDs, per se, needing further improvements or is it to do with cargo handling/loading, etc.?

The ULDs are designed to be restrained by the aircraft’s cargo loading system. During flight, the devices become part of the aircraft structure and are therefore, like any other aircraft component, subject to regulations to ensure flight safety. This is why it is so important to inspect the ULDs for serviceability before each deployment.

However, improper handling of ULDs after the check, for example during loading, can in the worst-case lead to bending of the fixing rails of the ULD and, in extreme cases, prevent the locks from being properly engaged in the aircraft. Responsible handling of ULDs is therefore essential for flight safety at all times.

Are there ULDs which are ‘fail-proof’ and what kind of training goes into handling ULDs, particularly for dangerous goods?

IATA has developed and maintained regulations, standards and procedures for the handling of dangerous goods.

As a partner of the IATA ULD Board and ULD CARE Board member, we contribute our expertise to the development of these standards, and we are also in contact with customers and ULD manufacturers to ensure that dangerous goods can also be handled efficiently and safely. However, it is essential that the people involved are properly trained to ensure adherence to all requirements.

With digitalization/AI, among many other smart technologies, making significant forays in air cargo movement, could you tell us how this can be factored in ULDs?

Managing a fleet of more than 100,000 ULDs efficiently around the globe requires high-quality data as well as the ability to analyze it professionally. To achieve this, we rely on highly developed digital solutions.

Our in-house developed IT solution JettWare offers transparent and real-time station inventory, ULD history and movement tracking as well as a variety of reporting options. Our advanced version, JettWare NG, already features initial artificial intelligence functions and will be continuously updated to provide even better workflow support.

In collaboration with university partners, Jettainer has also developed a sophisticated decision support system for ULD management that utilizes big data and machine learning. This enables us to better understand ULD journeys and predict ULD imbalances, allowing us to act rather than react.

To further increase transparency and gain valuable insights into optimizing ULD usage time, Jettainer has created digital twins for each ULD in its fleet.

Digital Twins are the home of all existing data of a ULD. They help to increase usage, drive down maintenance costs, and deliver easy access to the huge amount of data that is or will be generated through digital tracking with IoT solutions, ONERecord integration, and legacy integration with CargoIMP to all important cargo handling systems.

Do you have any product which aims at better transparency and improves ULD handling and flight safety?

Providing our customers with the best ULD management service is our core business, and transparency along the entire ULD journey is the key to efficiency and effectiveness. Our mission is therefore to use digital solutions to link all relevant data for us and our customers and thus generate added value.

The handling of ULDs is not up to us, but we offer training courses on the correct treatment of ULDs, raise awareness of the topic and never tire of emphasizing that ULDs are a valuable resource and an important part of aviation safety.

Could you run us through the special purposes’ aircraft ULDs such as temperature-controlled containers; ULD for animals; dangerous goods, etc.? How are they secured, particularly when there is turbulence?

Jettainer offers ULDs to securely load and move horses, cars, e-commerce shipments including lithium batteries, jet engines, big pets travelling with passengers, fresh fish, fruit, flowers, etc. including the service to lease these cool ULDs from providers such as cSafe, DoKaSch, or Envirotainer.

All of them are securely connected to the loading system of the aircraft and together with the aircraft handling manual and the ground operations manual, airlines and handling agents are able to avoid shifting cargo during turbulence.

Jettainer also supports customers with ULD serviceability and awareness training.

What are the challenges for an ULD team and how do you think this needs to be addressed?

For airlines, ULDs are essential in order to fulfil their core business: transporting passengers and cargo. Managing ULDs, in a most efficient way, is our DNA.

We relieve airlines from these tasks of ensuring that the right number of ULDs are always available in the right place. And we manage dedicated ULD fleets with only 80 percent of the units previously required. As a result, this ULD potential saving of 20 percent can either be used for growth or contributes to simply save cost.

Has the demand of airlines to ULD designers to create collapsible containers been met – such that airlines can load with cargo in one direction and then return as a flat pack?

We already provide our customers with collapsible horse stalls and collapsible LD3 baggage containers. This clever solution reduces costs for repositioning empty ULDs and helps us and our customers to maximize fleet utilization.

We are told that automated tracking system for ULDs has not gained momentum, if so, why?

Tracking the path that our ULDs take in global networks is essential – not just for our customers, but also for our management process we need precise data.

This can be achieved in various ways. We equip our customers’ fleets with IoT technology, if we gain useful advantages. However, current trackers are often dependent on the associated reader infrastructure, which sometimes reaches its limits outside the warehouse or at least the airport.

In the end, it’s all about data. And this is our main focus at the moment – to use data that is already being generated in large quantities during freight and baggage transport, linking and processing it in a meaningful way. We are already using this approach, and thanks to our in-house IT solution JettWare, we know very reliably and precisely where our ULDs are located at airport level – so our customers can rely on ULD availability.

This brings us also closer to our goal of making the journey of ULDs outside the airport more transparent. We are therefore currently developing and expanding APIs with customers and partners. These APIs are a smart way of handling data in order to improve operational efficiency and service quality. And we are also preparing to adopt the IATA ONE Record Standard for all areas of ULD management.

Tell us about your operations, growth and the opportunities you see in ULD?

Although I have only been CEO of Jettainer since June this year, I have known the business from the customer perspective for a very long time. I can definitely say that our team is excellently positioned.

Our experts live and breathe ULD management, and we have the suitable digital solutions to meet even highest customer requirements with our services at all times and offer significant added value. We want to growth further on the path we have embarked on in the long term and, with an openness to innovation, continue to convince with leading services in the future.