Modern WMS cuts costs where possible

Market for digital solutions enhancing

productivity without extra labor costs

projected to rise multi-fold

The WMS market size is projected to reach $3,112 million by 2022, growing at a

CAGR of 15.2% from 2016 to 2022. This can be attributed to the increase in

inventory and workload of WMS in warehouse operations.

With recent technological advancements and the

r i s e i n d e m a n d f o r

warehouse management systems

(WMS) in retail and third party

logistics (3PL) application, the WMS

market is expected to be stronger in

the coming decade.

The WMS market size is projected to

reach $3,112 million by 2022, growing

at a CAGR of 15.2% from 2016 to 2022.

This can be attributed to the increase

in inventory and workload of WMS in

warehouse operations.

Europe is expected to be the largest

market during the forecast period,

according to Global Warehouse

Management System Market by

Component Type, Industry Vertical,

and Geography—Global Opportunity

Analysis and Industry Forecasts,

2014–2022 published by Allied

Market Research (AMR).

Air Cargo Update sat down with

Naval Sabharwal, Global Head –

Supply Chain and Logistics, Ramco

Systems to discuss the benefits of

using WMS in the cargo industry.

WMS

The evolution of WMS is very similar

to many other software solutions. A

WMS manages the warehouse

operation. It performs in real time,

m a n a g i n g l a b o u r, m a x i m i z i n g

e q u i p m e n t a n d t r a c k i n g a n d

controlling inventory. In doing this, it

maximises labour productivity and

minimises errors.

WMS is available in wide range of

technologies. However, Java and

.NET are the basis for many of the

warehouse management systems

available in the market. There are

ma ny t y p e s of wa re h o u s e s a s

follows; Raw Material Warehouse,

WIP Inventory Warehouse, Finished

Goods Warehouse, Distribution

C e n t e r s , C l i m a t e C o n t r o l l e d

Warehouse and Special Warehouses

such as Bonded Warehouse and Free

Trade Zones.

A modern trend

In WMS, inventory management is an

asset and is defined as any property

intended to meet the requirements of

customers throughout the business

cycle. It adds to the cost of operations

irrespective of the form it is in – be it

r a w m a t e r i a l s ,

W I P g o o d s ,

finished products

and inventory in

transit and it is

important that the

i n v e n t o r y i s

managed at an

optimum level to

improve the cost

revenues of the

o r g a n i z a t i o n

w i t h o u t

compromising its

ability to meet the

ongoing demands

of its operations

and to meet its

c u s t o m e r s ‘

requirements.

“The advent of

software technology in this space has

r e s u l t e d i n o r g a n i z a t i o n s

implementing modern inventory

management system to achieve this

c o v e t e d b a l a n c e . W i t h t h e

emergence of Mobile technology,

smartphones to are gaining the upper

hand in managing the inventory. A

large number of business owners

have been able to access real-time

information about their inventory onthe-

go.

“Balancing customer and vendor

relationship is a critical aspect in the

supply chain and has often been

considered the essence of supply

chain management. However, closer

examinations reveal that the heart of

these relationships is inventory

movement and storage. Most of the

activities involved in managing the

vendor-customer relationship are

based on purchase, transfer, or

management of inventory. Hence,

i n v e n t o r y i s a f u n d a m e n t a l

component of the supply chain, and

its primary purpose is to feed the

customers’ requirements across the

supply chain”.

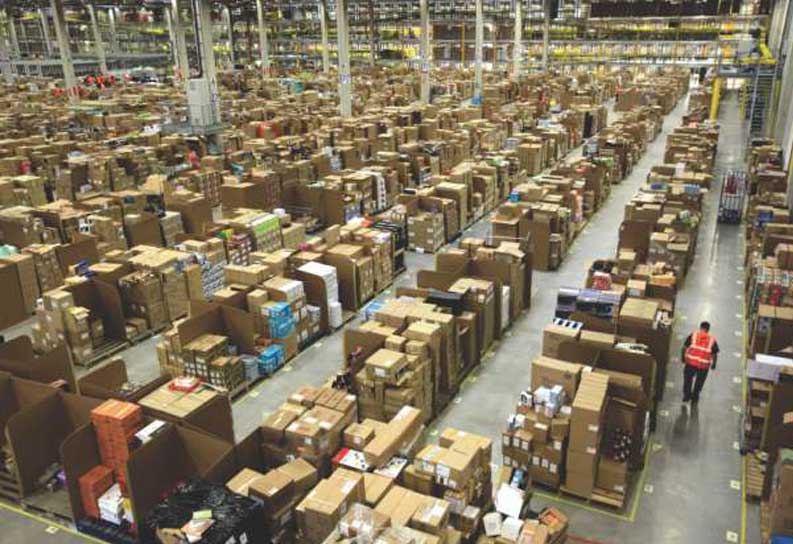

An auxiliary of trade

Warehouse helps to store the

inventory in all forms safely and

securely until the point of purchase or

consumption by the customer.

“In today’s world where demands are

volatile and replenishment times are

long due to globalization, achieving

100% JIT (Just in Time) or a Kanban

model is impossible, and this calls for

a build-up of certain types and

quantities of inventory at various

s t a g e s o f t h e s u p p l y c h a i n .

Warehouses provide the means to

store such inventory in a safe and

secure manner”.

Helping warehouse operations

Warehouse managers today have an

array of technologies to choose from,

to streamline operations, reduce

costs and improve performances. A

few key aspects where technology

come to the rescue are – optimizing

w a r e h o u s e p r o c e s s e s a n d

operations, enhancing productivity,

increased visibility of inventory,

improved utilization of resources and

enhanced customer satisfaction.

A superior WMS improves space

utilization in the warehouse by

informing the operator where to put

the item by selecting a storage

location that best fits the product. It

c a n a l s o i m p r o v e w a r e h o u s e

capacity, allowing goods to move

more quickly through the facility and

at the same time reducing handling

and storage requirements.

Like any other software, WMS is a

software which helps to streamline

and optimize processes and will

require manual interaction to some

degree for it to be able to perform the

tasks.

“ U n s u s t a i n a b l e a n d p e o p l

dependent core activities of a

w a r e h o u s e s u c h a s p l a n n i n g ,

resource allocation and directing

execution are automated by WMS

with little support from operators”.

Mobility availability

T h e w a r e h o u s e i s a l l a b o u t

movement and tracking, and the

availability of mobility feature in

W a r e h o u s e w i l l e n h a n c e

p r o d u c t i v i t y a n d o p e r a t i o n a l

efficiency. Hence, mobile technology

has indeed become a necessity to

keep pace with the technological

trend.

Asked if WMS provides mobility,

accuracy and efficiency at Ramco,

Naval responded positively by

saying, “We certainly believe that

WMS streamlines, automates and

enhances warehouse operations

significantly. At its most basic, it

improves the efficiency and economy

of movement within a warehouse

with its logical planning thus reducing

the number of ‘touches’ a material

receives – the most important

objective of any warehouse. Through

automatic data capture and mobility,

it improves accuracy in operations –

say picking or put away – and

a s s o c i a t e d d o c u m e n t a t i o n b y

eliminating the manual entry which is

certainly error prone”.

High productivity levels

A well designed WMS increases

labour productivity by managing

wo r ke r ‘ s t a s k s . I n a d d i t i o n t o

directing labour, WMS also provides

l a b o u r p l a n n i n g f e e d b a c k t o

management. That feedback is then

used for estimating peaks and valleys

in product activity.

“Labor productivity is increased

through optimal work allocation to

resources based on their skill sets,

qualification, performance and

a v a i l a b i l i t y a n d t h e e r r o r s i n

operations are minimized through the

Automatic Data Capture mechanism

that is used in the operations

controlled by WMS.