Peli Bio Thermal The leading provider of thermal protection solutions

“CoolPall™ Flex is a product that we designed to fit a gap in our single use product line. It is designed to be used on smaller, regional aircraft. It has a lot of flexibility, as its name suggests, whereby it can be tuned up or down in terms of performance by adding extra coolants or taking them away or adding additional insulation. It is a very flexible product and there are more than 300 possible combinations of CoolPall Flex based on the sizes and configurations of it. We have seen a lot of success with selling the product since we introduced it to the market in 2018.” – Adam Tetz, Peli BioThermal Director of Worldwide Marketing

Pallets, those platforms made of wood or metal with flat surface used to safely transport goods of all kinds, have always been an integral part of the air cargo industry. There are many different types of air cargo pallets, and each type is designed for a specific type of goods to safely transport them anywhere, under any circumstances. From food and medical supplies, to clothes and electronics, to other high-value goods, the pallets help keep items securely in place during transit. .

The global pallets market size was valued at $66 billion in 2015, and is projected to reach $122.3 billion by 2030, growing at a CAGR of $4.6% from 2021 to 2030 (Allied Market research).

The e-commerce industry’s unprecedented growth is expected to significantly increase the demand for pallets. The Covid-19 pandemic has made more people turn to e-commerce platforms, especially in countries like India. This increase in the popularity of ecommerce has challenged supply chains to develop better transportation and logistics

in order to control the flow and cost of outgoing and incoming goods. Online orders are usually small and more frequent, so they require more resources to manage. This creates a demand for pallets for ecommercebased logistics, which drives the pallets market growth.

Adam Tetz, the Peli BioThermal Director of Worldwide Marketing, explains how their highly customized CoolPall™ Flex can tailor bulk shipments to specific performance requirements.

CoolPall™ Flex

The CoolPall™ Flex bulk shipper is highly customizable, able to be adapted to specific shipping lanes or performance objectives. This temperature-controlled shipper provides excellent thermal protection at the lowest possible cost.

The bulk shipper is available in water- or PCM-based coolants, in singleor double-pod configurations (giving additional performance but with slightly reduced payload), with optional VIP insulation and in 3 different sizes. Payload volumes range from 150 – 757L with performance in excess of 140 hours.

“CoolPall™ Flex is a product that we designed to fit a gap in our single use product line. It is designed to be used

on smaller, regional aircraft. It has a lot of flexibility, as its name suggests, whereby it can be tuned up or down in

terms of performance by adding extra coolants or taking them away or adding additional insulation,” explains Tetz.

“It is a very flexible product and there are more than 300 possible combinations of CoolPall™ Flex based on the sizes and configurations of it. We have seen a lot of success with sell ng the product since we introduced it to the market in 2018.”

Packaging design

The type of goods carried by a pallet can vary greatly, depending on the specific industry and application. For example, in the food and beverage industry, pallets are often used to transport perishable items, such as produce or meat.

In the construction industry, pallets may be used to transport heavy building materials, such as bricks or concrete. Pallets can also be used to transport a variety of other items, including chemicals, automotive parts, and electronics.

Choosing the right-sized pallet is crucial to keeping air freight shipping costs low. If products are placed on an incorrect-sized pallet, it makes them less secure and creates extra space on the flight, resulting in higher shipping

costs. Luckily, plastic pallets are available in a variety of sizes to ensure that goods are securely and efficiently shipped.

“Our packaging is designed for the shipping of high – value pharmaceuticals and because these pharmaceutical payloads deal with human health, the shipper solution must have exceptional performance.

“Items carried would be either pharmaceuticals or active pharmaceutical ingredients (API), which could be in the form of large drums of active pharmaceutical ingredients, which are the precursor to packaged drugs. Our packaging protects the cargo from a temperature excursion that would damage the payload because CoolPall™ Flex protects, no matter what the temperature is outside, whether it is very hot or very cold, the payload space would still be protected.”

The global pallets market size was valued at $66 billion in 2015, and is projected to reach $122.3 billion by 2030, growing at a CAGR of $4.6% from 2021 to 2030 (Allied Market Adam Tetz research).

Proper handling

Proper handling of aircraft unit load devices (ULDs) is essential to avoid the $330 million in annual repair costs the industry incurs, 80% of which could be prevented. aircraft damage during ground operations. Careful attention must be paid to ULD build-up to ensure it is the correct size, type and structurally sound for shipping, as well as clean. Goods should be interlocked when loading onto the ULD, or, if not possible, held in place with ropes or straps underneath the pallet nets.

The global unit load device market size was $2.15 billion in 2019. The global impact of COVID-19 has been unprecedented and staggering, with unit load devices witnessing a negative demand shock across all regions amid the pandemic. The market is projected to grow from $1.98 billion in 2020 to $2.67 billion in 2027 at a CAGR of 4.38% in the 2020-2027 period. The sudden rise in CAGR is attributed to the market’s demand and growth, returning to pre pandemic levels once the pandemic is over (fortune business insights).

“It is one of the key components of all of our pallet sized products, including CoolPall™ Flex. We did extensive research and integrated a pallet system into CoolPall™ Flex which works well, and we have since upgraded that with a newer system that we think will again be complimentary to that purpose.

“CoolPall™ Flex is a single use product. We put in as much durability as we can to save cost and weight for a product that’s going to be used one or two times. It is definitely a component of our math when it comes to building and designing the product.”

Impact of Covid-19 on pallet management

COVID-19 has impacted everything within the supply chain and the pallets industry wouldn’t be an exception to that. Issues have included the fact that pallets were less readily available during the pandemic. What industry have seen has been a move to try to use reusable pallets, to use plastic pallets instead of wood pallets, according to Tetz.

“There were situations during the COVID-19 pandemic where we didn’t have enough pallets, or we ran low when it came to pallet availability. So pallet management is important especially if it’s a key component within your business and your products are shipped on pallets, which ours often are. This is the case when it comes to the CoolPall™ Flex as it will go, when it is being shipped to a customer, on a wood pallet in its component pieces. Pallets are critical for shipments in and out of our manufacturing and warehousing facilities and during the pandemic the supply of pallets was certainly impacted,” he added.

Further noting that sometimes in pharma logistics there is a preference to use plastic pallets over wood. This is because the plastic pallets are less likely to be a host for germs and bacteria because the wood has more surface area due to its varied texture alongside having the potential to be chipped or damaged by fork lift trucks.

“So, what we are seeing within the industry is a preference, where possible, to use plastic pallets; however they are more expensive than wooden versions. A big element of what we do with our smaller parcel sized products is that we have to configure them so they will easily fit, in a maximum efficiency way, on both the European (Euro) pallet size and the ISO pallet size for North America. It is a key component of the way we design our products to maximize the savings for our customers, by maximizing the efficiency around both weight and volume,” said Tetz.

“We have developed technical tools that assist with planning out exactly how many of our parcel products will fit on a pallet. We do that because our customers need that efficiency calculation when they purchase products from us.”

When asked why pallets are as much important as a refrigerated trucks or ERP systems, Adam replied, “Absolutely, pallets play a pivotal part in our operations. We ship our parcel sized products out in component pieces to our customers and they put together and pack the payload, then they are palletized. We have technical tools to help assist with how to best load those onto a pallet to maximize the payload per pallet. Pallets are critical to our business and without them we wouldn’t be able to ship.”

Expansion in China

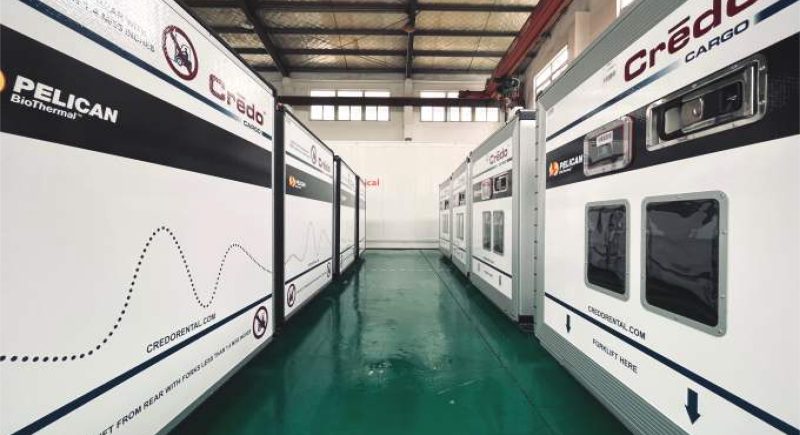

Peli BioThermal, recently announced the opening of its first network station in China. Located in Shanghai, the new network station will serve worldwide customers of the Crēdo™ on Demand rental program.

According to the company, China is a growing component in the global market for manufacturing and distribution of pharmaceuticals, including as the leading producer of active pharmaceutical ingredients and a top producer of generic drugs. Through the ‘Made in China 2025’ plan, China aims to further grow its pharmaceutical industry, focusing on drug innovation through research and development.

China’s pharmaceutical market continues to be an area of significant growth. According to the International Trade Administration, China’s pharmaceutical market value reached almost $134 billion in 2018 and is expected to grow to $161.8 billion by 2023.

Shanghai joins Peli BioThermal’s network of more than 100 network stations and drop points around the world and is the fourth network station in the Asia-Pacific region.

“A primary focus of our products, and year after year it continues to grow, is reusable rental products. So therefore expanding our service network worldwide is important. China is a major economic player on the world stage and an important destination, so adding Shanghai into our service network was something we had been looking to do for a number of years. We are very pleased to have finally added that site in China,” said Tetz.

The supply chain crunches are starting to ease. Wood pallets will continue to be primarily used because they are considerably less expensive than plastic pallets. COVID-19 will continue to have an impact on the pallets industry, but the supply chain crunches certainly seem to be easing, Tetz noted.